Financial Capital

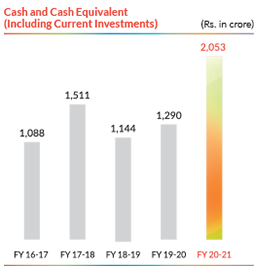

Thermax continues to make the right investments to foster resilience and create a more sustainable future. Despite the global challenges faced during the year, Thermax sustained its investment proposition, at the back of its integrated value chain, multi-sector approach and highly skilled people. Additionally, prudent risk management and focus on cash conservation helped the company navigate the challenges to end the year with a strong cash position of Rs. 2,053 crore.

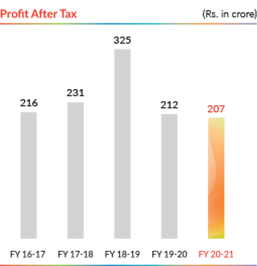

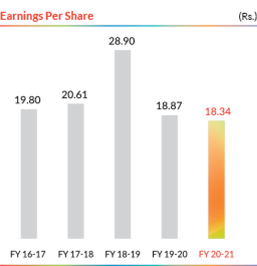

The company uses the cash generated from its operations, as well as from debt and equity financing, to grow its business and ensure sustainable value creation for its stakeholders. Financial Capital is reinvested in other capitals to strike the right balance between profitability and cash flows. Investments in digitalisation helped Thermax improve its internal process efficiencies and customer experience. Further, project ‘Agile’, aimed at bringing rigour into indirect cost reduction, yielded cost saving and improved profitability. As the company continued to build capacity to capitalise on the growing opportunities during the pandemic, it focussed on driving efficiencies and productivity by investing in operational excellence initiatives.

Through investment in ThermaxNXT, its transformation project, the company aims to scale up revenue growth in its identified businesses. The project is focussed on building an organisation that drives excellence, inclusivity and innovation. For more details, refer to Propelling a Sustainable Growth Strategy on click here

During the year, Thermax also made investments in further augmenting its R&D capabilities. Its R&D centre deploys cutting edge technologies through technology tie-ups to develop unique applications for customers. This enables the company to deliver on its brand promise of ‘Conserving Resources, Preserving the Future’. Thermax is currently working in the areas of new energy, such as fuel cells, Thermal−HVAC and bio CNG. Thermax subsidiary TOESL is setting up a compressed biogas project through its newly formed subsidiary Enernxt Private Limited.

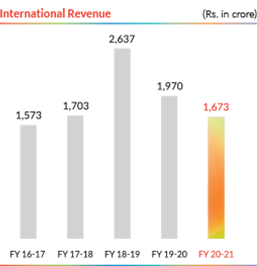

To further boost efficiencies, Thermax undertook restructuring during the year in its global operations to consolidate its presence. Impairment of assets was made post assessment of the recoverability of investments made in Thermax Netherlands B. V. and Thermax Engineering Singapore Pte Ltd. of Rs. 74.68 crore and Rs. 22.49 crore respectively. In another move, Thermax closed down its China subsidiary – TZL (Thermax (Zhejiang) Cooling & Heating Engineering Co. Limited, China) and has proposed liquidation of Thermax Senegal S.A.R.L, post winding up of operations. Thermax also sold a non-profitable service business segment of Boilerworks A/S. Entities have been established in Thailand and Nigeria to steer the expansion of the project business overseas.

TOESL proliferates the tyre industry by commissioning an 18-tonne biomass fired boiler plant for a Japanese tyre manufacturer

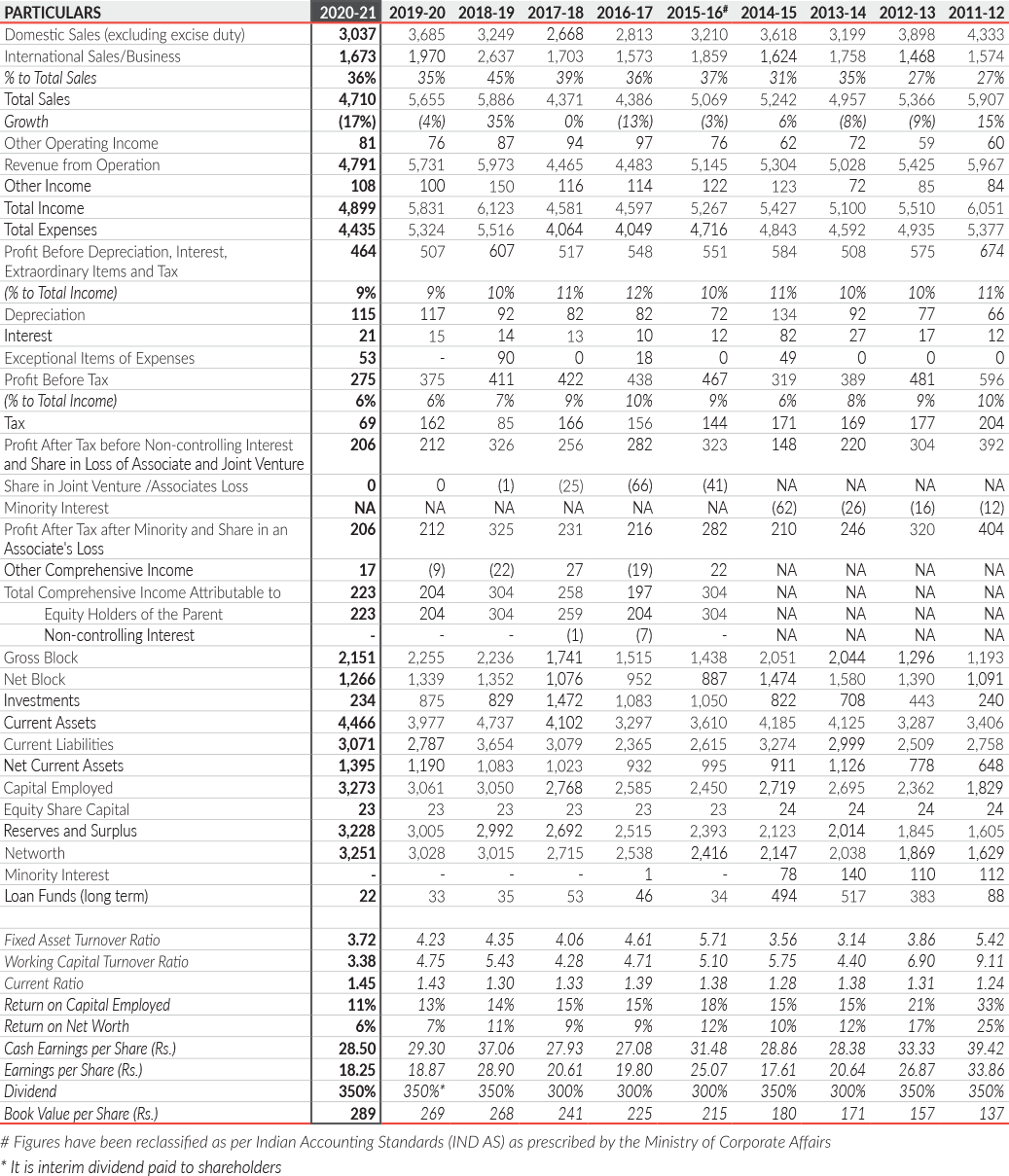

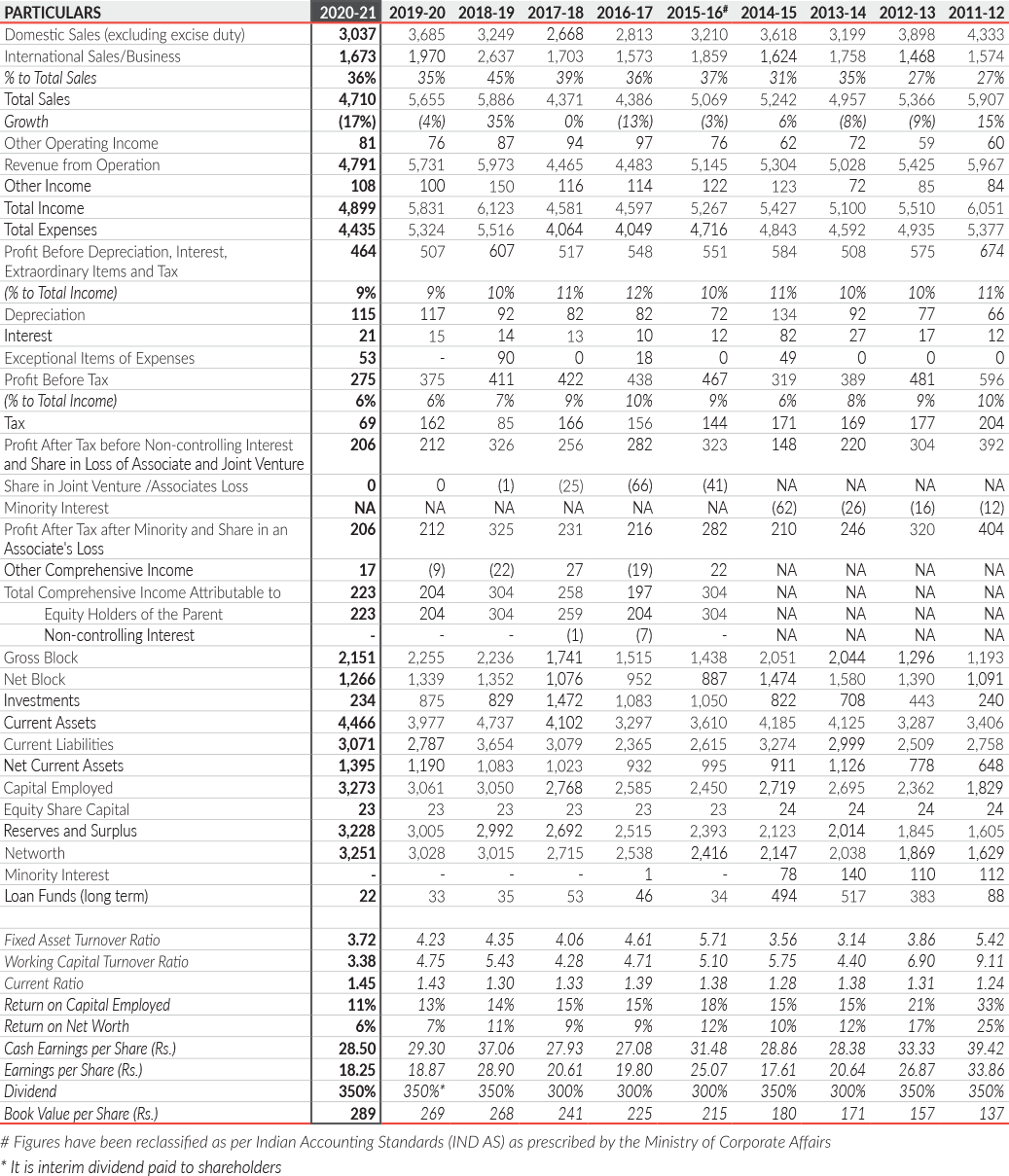

Key Financial Indices

Thermax Group

Financials at a Glance

Thermax Group

MANUFACTURED CAPITAL

With strategic investments in its plants and equipment, Thermax converts its resources into high value solutions. These investments also help to enhance production as well as the safety and reliability of operations. Additionally, it enables the company to effectively manage its environmental footprint and comply with the regulatory requirements.

Thermax is a leading manufacturer of capital goods that meet the utility requirements of diverse industries globally. The company is present in 88 countries. The manufacturing facilities are ISO 14001:2015 and ISO 45001 / OHSAS 18001 certified. They are inspected by Lloyds, Bureau Veritas, SGS and TUV. Thermax manufactures as per international standards – ASME, BS, DIN, GOST, API, and CE, besides the IBR code in India.

Through its Manufactured Capital, Thermax continues its pursuit to provide clean and green offerings to its customers. Its facilities strengthen the company’s capabilities to execute complex projects in the domestic and overseas markets. Its operational excellence helps the company integrate its people and processes in a seamless manner, resulting in better performance – financially and non-financially.

The company’s Manufactured Capital enables it to engineer sustainable solutions that fulfil customers’ needs, and thus, warrants strategic consideration and due investment. Thermax has a strong manufacturing edge built on targeted initiatives. These initiatives include supporting customers with utility needs for greenfield facilities; upgrading the capacity of existing facilities; deploying technologies such as modularisation; and service based on the Industrial Internet of Things (IIoT).

Thermax Solar expanded its international presence by installing its first solar PV plant of 1 MW capacity in Kenya, Africa, for a leading edible oil manufacturer

During the year, the manufacturing operations across industries were impacted due to the COVID induced lockdown. Challenges continued even post the resumption of operations, with pandemic safety protocols making it difficult to scale back to normalcy. Despite the problems, the Heating plant at Savli not only effectively managed the backlog built during the lockdown period but also clocked the highest ever production in December 2020. Resilience of the

workforce and cross-functional synergy between different teams including providing on-time inputs to delivering the highest manufacturing output, led to this exemplary achievement. Thermax’s latest state-of-the-art Cooling plant at Sri City continued to leverage its automation capabilities, and delivered 30 machines in September 2020 - the highest number of units in a single month.

With the commissioning of Phase II of resin production at Thermax’s Dahej plant in Gujarat during the year, manufacturing capacity at the facility went up to 20,000 m3 per year from 10,000 m3 in the previous fiscal. This challenging task was managed in spite of the severe damage caused by an explosion in an adjacent chemical facility.

Success Stories

Remote commissioning of a boiler in Egypt

Remote Commissioning of Auxiliary Boiler

One of the key projects executed by Thermax during the pandemic was the remote commissioning of a large auxiliary boiler in Egypt. With meticulous planning and execution, TBWES commissioned a unit of 50 TPH natural gas, acetone and water gas fired boiler for a chemical company. All critical processes were carried out through Remote Online Service Support (ROSS). The operations were conceptualised with adequate SOPs and O&M manuals, and a live view of the Data Collection System was conducted. The project paved the way for Thermax to develop a service model that can yield substantial cost savings for its customers. At the same time, this will help increase workforce productivity by enabling employees to support multiple sites simultaneously.

HUMAN CAPITAL

Thermax remains steadfastly focussed on nurturing a healthy organisation and a capable workforce, with an inclusive approach to its human resources. At the core of its people policy is the company’s thrust on building and retaining its critical skills, enhancing its performance potential, and developing its leadership capabilities.

While the Thermax values have been the company’s guiding light, the Executive Council has also formulated a set of behaviours that define a true Thermaxian. These behaviours serve as a beacon in the overall development of an employee. The Thermax behaviour code is centred around: Customer (customer centricity), Lead, Own, Create, and Collaborate, briefly known as CLOCC.

CUSTOMER

Ability to put the customer first in everything the company does (internal as well as external); awareness towards industry trends and customer needs, demonstrated through relationships built with the external world.

LEAD

Thermax culture encourages taking calculated risks, while seeking new frontiers, and in pursuit of addressing unique challenges.

OWN

With dependability, trust and responsibility, owners consistently meet commitments made to customers, peers, teams and managers.

CREATE

Being builders, creators and innovators; the change is exhibited through new products, software and business models.

COLLABORATE

Building strong formal and informal networks, thriving in matrixed relationships, and driving success by leveraging the power of teamwork.

Health and Safety

With health and safety of employees taking centre stage amid the COVID-19 crisis, Thermax stepped up the momentum of its wellness programmes during the year. Various initiatives were launched to help employees deal with challenges, keep up their morale, and stay connected. All the health-related days were observed through activities like ‘yoga’ sessions, talks by professional experts on relevant topics like cancer, mental wellness, and so on. Spouses of the employees were also encouraged to join.

The company created a Wellness app in collaboration with its health partner - Health Positioning System (HPS) Wellness, to enhance the wellness quotient of employees at physical, emotional and social levels. The app provides a comprehensive and multi-dimensional health enhancement programme, personalised to the employee’s ‘Prakruti’ (age, gender, diet and current health status). More than 2,000 employees have been engaged through the app.

Upskilling safety officers to align with international standards in occupational health and safety is a key priority at Thermax. The Safety app was revamped by the Business Technology Group and Health, Safety and Environment (HSE) teams to enhance its functionalities. Its advanced and dynamic dashboard facilitates the managing team in accessing more transparent, accurate, simple and handy data, thus saving time from reporting to closure by 25-30%. The feature-loaded app has seen a user increase from 2,100 to 3,400 within three months of its launch.

Themed ‘Save yourself to save your family’, the Road Safety Month was celebrated from January 18 to February 17, 2021, across locations, offices and customer sites. The celebrations were marked by online quiz, safety bulletins, training on mobile vehicle safety, PUC check-up and check-ups of all transport vehicles.

The National Safety Week, celebrated from March 4 to 11, 2021, was themed ‘Learn from disasters and prepare themselves for a safer future’. More than 17,785 people, including Thermax employees and workmen, third party staff and other contractual workforce, participated in the activities.

Employees take the safety and environment oath during the Road Safety Month

Nurturing Talent

The progressive growth-led people culture at Thermax has enabled many employees to rise through the ranks, while several have assumed critical leadership and senior management positions over the years. The company recently formalised a policy on Talent Mobility, which encourages employees, identified as talent, to look for lateral or vertical shifts. The policy is designed to inspire employees to take up new positions that augment and diversify their existing potential. It also enables managers to adopt robust processes to manage people movement, and gain from multi-faceted talent. The HR team encourages managers and individual contributors to adopt talent mobility, by sharing blogs on success stories of employees.

The learning curve of the employees continued through the pandemic. ‘Maximise Learning’ was launched, as part of which 159 internal technical subject matter experts joined hands with L&D trainers. Over 300+ behavioural and functional sessions were conducted for 27,047 hours, which helped maximise learning for 3,000+ learners.

Through its Managerial Development Programme, aimed at middle-level managers, Thermax targets building of managerial capability and ability to drive performance. The company’s Learning and Development team leverages the expertise of Business Unit heads to deliver functional training. Consistent utilisation of concepts, across divisions and functions, helps the team move closer towards ‘One Thermax’. Key competencies identified for the training are: techno-commercial decisions and contracting, strategic/execution decisions, driving performance, developing people, managing change, and communication.

Scale-up – a collaborative sales intervention programme of the company, is helping it develop and enhance B2B sales development skills and competencies in managers. A first time managers’ programme, called ‘ACE’, is aimed at developing skills for employees who have transitioned from an individual contributor to the role of a team leader within the last 18 months. It focusses on bringing change, developing the team, and steering performance.

Success Stories

Becoming Knowledge Partners through L&D Programmes

The Water and Waste Solutions division partnered with a globally renowned food and beverage company to deliver a training module, ‘Site Expert Trainer’. The module was crafted to help the operations team in Africa, Middle East, South Asia (AMESA) division manage tasks and improve alignment with sustainability. The programme delivers a user-friendly and interactive step-by-step knowledge repository. After experiencing benefits from the first module, the customer awarded two more projects to the company for locations outside India. The initiative’s success enabled Thermax to make training a business proposition, and firmly position itself as a knowledge partner.

INTELLECTUAL CAPITAL

Thermax has a rich Intellectual Capital repository, comprising a robust knowledge base, including its patents, rights and licenses, research and development policies, systems, procedures and controls. The company is continually strengthening its Intellectual Capital through process and business model innovations, R&D efforts, as well as initiatives on operational excellence and digitalisation. The cumulative value of the Intellectual Capital that Thermax has refined over the years, drives its evolving business strategy.

The company is among a few, globally, to offer integrated innovative solutions in the areas of heating, cooling, power, water and waste management, air pollution control and chemicals. It has a reputation for inculcating proven global technologies in customer processes, to improve their resource productivity. Its multi-sectoral technology prowess enables Thermax to promote green technologies, including waste heat recovery systems, flue gas desulphurisation systems, power from waste and renewables, helping customers reduce carbon footprint.

Thermax’s long-standing Research, Technology and Innovation Centre (RTIC), equipped with around 111 R&D engineers and scientists, is constantly working on developing new and cutting-edge technologies and upgrading existing technologies.

The company celebrates Technology Day, Dr. N. D. Joshi award, and Operational Excellence awards, besides rewarding its employees for business innovations.

Digitalisation of offerings and operations helped the company scale up its presence in relevant markets amid the pandemic. It continued to harness the power of digitalisation to deliver customer-centric applications that add value to customer processes. Considering the complex nature of its offerings, Thermax deployed a robust automated proposal generation process, addressing customer requirements accurately, with improved response time. It further augmented its capabilities in remote commissioning and monitoring of equipment. To enhance its EPC capabilities, the company introduced 4D BIM (Building Information Modelling). It also developed an in-house app – ThermQ, to facilitate all EPC teams in planning, assigning, coordinating and seamlessly tracking projects.

A new solar microsite was created to provide customers with a comprehensive overview of the company’s solar PV offerings and share other relevant information. Thermax also revamped its website to put in place a more contemporary user interface, with new features. The revamp and search engine optimisation activities improved website traffic, with better ranking and consistent flow of enquiries. In line with its focus on digital marketing, the company leveraged social media channels, including YouTube, LinkedIn, Facebook and GoogleAds, for lead generation for select businesses. Promotional content was utilised to enable customers access specific product/solution-related information. Customers were also facilitated in capturing and tracking enquiries effectively, thus enhancing their experience.

Manufacturing Execution System deployed at the Sri City plant in Andhra Pradesh

Success Stories

Increasing Biofuels’ Share in India’s Energy Mix

To address the issue of burning of paddy straw stubble, Thermax launched bio-CNG technology in partnership with Pune-based Primove Engineering. The technology enables the use of difficult biomass to generate bio-CNG. This unique and high-yield bio-digestion process breaks down the lignocellulosic biomass in a digester, creating a new market in India. The technology can be deployed for several other straw type lignocellulosic biomasses. It provides a promising solution to replace carbon-positive fossil fuel with a carbon-neutral biofuel, and reduce import costs for natural gas. The carbon-neutral technology will help increase the share of biofuels in India’s energy mix by harnessing its vast and untapped agro-waste. It is a major step forward for the country to achieve its sustainability goals.

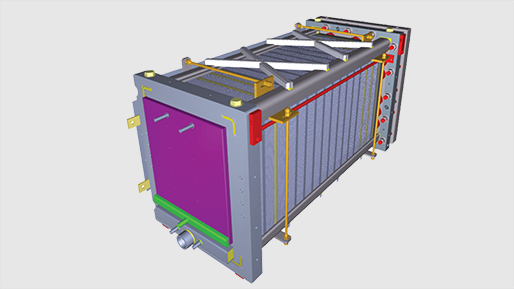

Making Vehicles More Fuel-Efficient

Thermax’s RTIC team developed and commercialised a first-of-its-kind T-HVAC (Thermal Heating, Ventilation, and Air Conditioning) product for mobility application. This waste heat recovery project has developed absorption technology, utilising engine exhaust heat. A 32 kW capacity of the T-HVAC unit, integrated with a 5-star premium coach, was approved by the German regulatory authority for meeting stringent homologation and roadworthiness requirements. The approval paves the way for the adoption of this technology across the European Union. T-HVAC provides the benefit of total cost of ownership, by achieving fuel savings in the range of 5-8%, thus lowering pollution. Thermax is contributing to a greener environment through its thrust on making vehicles more fuel-efficient, economically and environmentally.

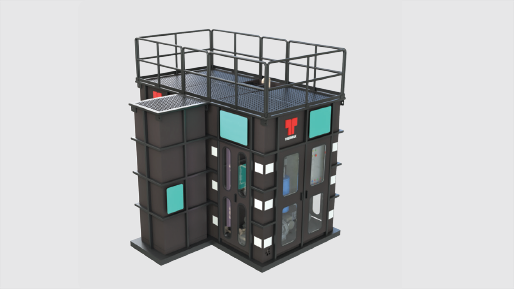

atoM

The Water and Waste Solutions (WWS) business of Thermax launched ‘atoM’, a completely modularised system to treat sewage water efficiently in confined spaces, such as basements. It incorporates Membrane Bioreactor based technology. Engineered for automated operations, it removes nitrogen and phosphorus from wastewater and provides consistent water quality with varying inlet loads, which is suitable for recycling and reuse. The product finds application in the Urban segment, with its contemporary aesthetics, sleek design, easy installation and automated operational features making it a perfect fit in commercial and residential spaces. Thermax received its first major order for atoM from an e-commerce giant for its Indian data centre in Hyderabad.

Thermax Fuel Cells for Indian Navy

Thermax has supplied fuel cell stacks for India’s home-grown Air

Independent Propulsion (AIP) system. The cells are designed to

significantly enhance the operational effectiveness of submarines.

For more details on the Highlights section click here

SOCIAL AND RELATIONSHIP CAPITAL

Thermax integrates the needs of its stakeholders, and delivers on its commitments, in order to create an enabling environment for its operations and investments. It maintains effective partnerships and relationships with its customers, suppliers, shareholders, dealers, employees, local communities and the regulators, among others. Its constant endeavour is to be responsive and solution-focussed, and to partner with stakeholders to achieve its strategic objectives.

Communities and Society

The company recognises that its business sustainability is premised on the relationships it builds with its communities. It acknowledges the importance of its societal welfare initiatives to promote sustainable growth. Its key objective is to facilitate quality education for children from economically weaker backgrounds, to help them come out of the vicious cycle of poverty. Further, Thermax Foundation works closely with the vulnerable communities around the company’s manufacturing locations, and encourages key projects based on need-based evaluation.

Due to COVID lockdown and subsequent physical distancing norms, the involvement of Thermax employees in community outreach programmes during the year was limited. However, the company endeavours to look at ways to involve its employees in contributing their skills and domain expertise towards addressing critical social challenges.

The School Project

Inspired by the belief that every child deserves access to quality education, Thermax Foundation (TF) continues to partner with The Akanksha Foundation (TAF) in strengthening the Pune Municipal Corporation (PMC) schools through a tripartite agreement. Among the PMC schools run by TAF, last year, TF funded K. C. Thackeray Vidya Niketan English Medium School and Savitri Bai Phule English Medium School; and also partially funded Matoshri English Medium School. TF also continued to handhold and mentor the alumni of Akanksha Schools, encouraging them to pursue higher education.

The success of the programme can be gauged from the fact that four alumni from Akanksha Schools joined Warburg College, Wheaton College, Whitman College and University of Oklahoma in the United States, respectively, post their junior college at United World College (UWC). Four others joined Ashoka University, while one got inducted into NIT Silchar.

Students of grade 10 from Savitri Bai Phule English Medium School attending classes when pandemic norms were relaxed

iTeach Alumni Support

Thermax Foundation has partnered with iTeach Alumni Wing Support programme to mentor 200 alumni from Teach for India. During the year 2020-21, TF funded iTeach to provide support and mentoring to alumni under the broad categories of foundational learning academics, mentoring, and employment readiness. Though there was a delay in the admission process due to the lockdown, all the alumni secured admissions in junior college, due to timely support and guidance by the iTeach project team.

CSR Near Factory Locations

The Manav Seva project at the Savli plant facilitated access to government schemes for eligible beneficiaries. The project was also implemented in Alindra, Manjusar, Lasundhra and Gothara. Responding to the pandemic needs, the contours of Churni project, being run in partnership with Srotoshwini Foundation, were changed from the programme’s focus on imparting tailoring skills to stitching COVID masks. The change assisted the 35 below-poverty women beneficiaries of Lasundhara and Manjusar villages to continue earning livelihood during COVID. Thermax Foundation purchased all 16,000 masks stitched by these women, ensuring a monthly average income of Rs. 4,000-5,000. These masks were distributed, through Thermax employee volunteers from Savli, to community dwellers of Jhumkal, Lambdapura, Paladi, Manjusar and Alindra villages.

The Foundation also worked with Haqdarshaks to spread awareness, and provide access to poor people, towards welfare schemes like old age doles, widow pension etc. The beneficiaries were people living near Dahej and Jhagadia factory locations in Gujarat. Some of them were also provided sustainable livelihoods as a result of this initiative.

Following the stream widening work done at Ranmasale village near Solapur, a few volunteers from the village were invited by Thermax Foundation’s NGO partner Manavlok to Ambejogai to learn best farming practices in water-deficit areas. This resulted in an increased yield of onions, despite the pandemic.

Thermax employees from Savli distribute masks stitched by women associated with the Churni

project, to communities near its factory location

Employee volunteering

Six employees from Leadership Development Programme of Thermax were selected to impact six NGOs through an ongoing support instead of one time volunteering. The team of volunteers tried to support their respective NGOs online through initiatives like developing websites for them and raising funds. However, due to the pandemic situation, travel restrictions and language barrier, the envisaged impact of the programme was not as anticipated.

Like every year, employees took part in the Joy of Giving Week. This year, the donation appeal was made to employees through the online programme called ‘Tea Talks’. Thermax employees responded with enthusiasm, and contributed towards the purchase of tablets for students from Akanksha Foundation, Teach For India, iTeach and Jagruti School for Blind Girls. This was to ensure that the students get seamless access to online learning. Thermax employees also contributed to the appeal from Hope Foundation for seed funding for women entrepreneurs from underprivileged families who had enrolled with them for various skills. With income of the family severely impacted during lockdown, the donation was to help them buy the equipment to start masala making or other basic accessories to start their own business. Thermax Foundation made a matching contribution to these NGOs.

Through Thermax’s women networking platform ‘Sakhi’, several activities were undertaken to increase awareness on health and wellness, and to sensitise women on social issues. In another project, Thermax employees from the Shirwal factory, along with their family members, painted COVID safety messages on 1,000 reusable cloth bags, working from the safety of their homes. These beautifully painted bags were distributed at schools and shops, and also to the local panchayat through the NGO, ‘Being Volunteers’.

Cloth bags with COVID safety messages painted by employees from the Shirwal factory were distributed in schools, shops and the local panchayat

Dealers and Vendors

During the year, Thermax maintained strong relationships with its dealers and vendors. Its Channel Business Group recorded its highest ever revenue in the last two quarters of the fiscal, despite the pandemic challenges. Meticulous planning and focussed growth initiatives led to this achievement. Along with channel partners, the Thermax team also displayed hard work and determination to ensure business continuity, while addressing customers’ needs. The team also proved its mettle by breaking through stiff competition in new geographies, and tapping into future opportunities, while continuing to take utmost safety precautions. A noteworthy achievement was the supply, erection and commissioning of a boiler for a leading pharmaceutical company, within stringent timelines. This landmark installation was attended by the Prime Minister of India.

Online training sessions were held to build supplier capabilities, and more than 80 vendors were trained during the year. ‘Supply chain sustainability’ series was organised for the company’s critical vendor partners, to build awareness on safety and the environment. The sustainability questionnaire is now included in the vendor registration process. Buyers from most of the SBUs worked along with the company’s suppliers to create awareness on sustainability. This resulted in improving the percentage of material sustainably sourced, from 30.4% to 35.6%.

Customers

Thermax continued to support customers in their sustainability efforts throughout the year. The solutions offered by the company helped the customers save energy and water, minimise pollution and CO2 emissions, enabling them to transition into green and ensuring sustainable operations.

The company focussed actively on providing timely solutions to essential services based customers on priority during the pandemic. For example, it provided a hot water generator to a hospital, and efficiency improvement solutions for a pharmaceutical laboratory.

The company’s commitment in this regard was also manifest in the supply of ion exchange resins to a leading US based water purifying products company and on-time export order execution.

Success Stories

A 1,500 kWp ground mounted captive solar plant for a Government of India entity

Installation of Solar PV Plant

Thermax recently commissioned a solar PV plant in Jabalpur, Madhya Pradesh, for a large construction and maintenance company providing infrastructural support to the Government of India. Spread across a 16,000 square metre area, the 1,500 kWp ground mounted captive solar plant is capable of generating more than 2.5 million units of ‘green’ electricity. It is equipped to cut down carbon emissions by 1,890 tonne every year, thus facilitating the customer’s shift towards sustainable energy solutions.

Serving Customers through O&M

Through its O&M services, Thermax facilitates its customers in optimising resource consumption, besides keeping their assets efficient and productive. The company’s O&M team leveraged its strengths to support an Indian conglomerate with businesses in textile and steel, save cooling tower make-up water by 0.5 M³/MWh at its 43 MW captive power plant in Anjar, Gujarat. The team studied the cooling tower parameters, modified the chemical dosing programme, and maintained all standard parameters. This helped the company cut down its water usage by 8,000 m³ water, saving over Rs. 80 lakh a year.

NATURAL CAPITAL

Thermax is committed to minimise the use of natural resources and the impact of its operations on nature. It remains committed to building its Natural Capital through resource efficiency and excellence in environmental performance. The company is constantly measuring and managing the impact of its business and manufacturing operations on the environment, and taking necessary measures to reduce energy, water and material consumption.

During 2020-21, Thermax enhanced its renewable energy portfolio and improved green energy consumption from solar and biomass i.e. 15,201 GJ or 5.2% of its total energy consumption. The company achieved energy savings of 17,464 GJ from various energy efficiency initiatives, resulting in a 30% improvement over the previous year.

15,201 GJ

Renewable energy consumed

2,79,312 GJ

Non-Renewable Energy

Consumption

17,464 GJ

Energy saved

2,174 tCO2e

Emission Savings

Water Consumption

Thermax follows a ‘reduce, reuse and recycle’ concept at all its zero discharge manufacturing plants. All the treated effluent is used for gardening, fire hydrant system and flushing in toilets, resulting in recycling of water. Rainwater harvesting is also facilitating the company in reducing its dependence on freshwater. The company’s water harvesting initiatives in Paudh, Jhagadia, Dahej, Sri City plants, and in its two offices in Pune, led to storage, consumption and groundwater recharge of 25,253 cubic metre of rainwater during the year.

8,09,018 m3

Water Consumption

2,16,413 m3

Water Recycled

25,253 m3

Rainwater Harvested

World Environment Day marked by sapling plantation

Environmental Protection

Through ‘Thermax Cares’, the company is inculcating environmental consciousness into the organisational culture. It has undertaken various initiatives to encourage the employees and their families to contribute to reducing the earth’s carbon and water footprint. This is being done through a series of planned “Know”, “Act” and “Become” programmes, involving meaningful activities aligned with the UN SDGs.

Nurturing Biodiversity

To promote sustainable biodiversity, the company planted 4,310 tree saplings during the year. It also planted saplings at customers’ sites, besides conducting competitions on ‘Conserve biodiversity to preserve humanity’ and ‘COVID-19 versus biodiversity’.

Thermax relocated and shifted 120 matured trees to a safer place at a customer’s Flue Gas Desulphurisation plant in Dhanbad. Environment Day was celebrated with the theme ‘Ecosystem Restoration’, and a learning module was launched on ‘Decarbonising Life’, to increase awareness and strengthen mitigation plans on carbon emissions.

Environmental Compliance

Thermax conforms strictly to all environmental laws, regulations and standards. All its plants comply with the permissible limits of Ambient Air Quality, with parameters like PM2.5, PM10, SOx and NOx. The stack emissions are also within the parameters, as prescribed by the Central Pollution Control Board (CPCB) and SPCBs. Waste generated is disposed of in a socially responsible and environmentally safe manner across the company’s sites. Also, hazardous and non-hazardous waste is segregated and handed over to collection vendors to dispose of, recycle or reuse, as applicable.