Steam Engineering Solutions

Answering the need for utilities for greenfield setups and industrial expansions besides consumable needs

Leading the Industrial World to Energy Efficiency

The Steam Division at Thermax delivers energy efficiency through state-of-the-art steam products. In-house engineering, a strong supply chain reaching out across India, and deep domain expertise in heating and cooling give us a competitive edge, furthered by a robust service ecosystem.

14+ Years

of utility consultancy and steam solutions

BEE Accredited

Energy services company

Embrace Energy Efficiency – Contact Us

Quick Glance Into the Complete Business Portfolio

Design and supply of New Steam Systems across large capital projects.

Experienced energy auditors carrying out Steam System Audits for process efficiencies and water and energy savings.

Energy Solutions built by system engineers for energy & steam savings, process efficiency, product quality, and plant health.

Maintenance & Repair services backed with supply of spares for end-user systems to operate at an optimum level.

Training courses to skill our client’s technical and maintenance staff to optimally run their systems.

Steam Distribution

Key Products Portfolio

Steam Traps

Steam traps are ideal for various applications – draining and venting system, removal of condensate from steam main lines, moisture separators and critical steam tracing applications.

Thermodynamic Steam Traps Salient Product Features:

- Hardening of the disc and seat ensures long life

- Provided with inbuilt strainer and blow down valve

- Compact – available in single/three port design

- Available in forged steel/stainless steel body with SS hardened disc

Float Controlled Steam Traps Salient Product Features:

- Rotary slide valve mechanism which operates effectively even at small differential pressure

- IBR approved float controlled trap

- Available in combination of Steam Lock Release (SLR) with thermostatic air vent

- Designed for varying loads with continuous discharge

Bimetallic Steam Traps Salient Product Features:

- Corrosion resistant bimetallic strip

- Hardened seating surface for erosion resistance

- Unaffected by water hammer and vibrations

- Installable in any position

- Suitable for main line drain for saturated and superheated steam & steam line tracing

Thermostatic Steam Traps Salient Product Features:

- Provided with built in strainer

- Resists corrosion and is unaffected by water hammer

- Increased heat recovery from condensate

- Forged carbon steel with SS internals

- Designed for varying loads with continuous discharge

- High air discharge for venting

Bellow Seal Valve

These are isolation valves welded to metallic bellows, valve stem, and bonnet – an impermeable seal that ensures zero leakage.

Salient Product Features:

- Available in the entire size range up to 250 NB

- Zero leak, zero maintenance valve

- Bellow seal valves with multiple points of sealing ensure safe operation

- Special integral stellited seat

Pressure Reducing Station (TPRS)

Ready to assemble module of control valves, isolation valves, pipes and fittings intended to reduce steam pressure to designed conditions. These are majorly of two categories – direct acting and control valve.

Salient Product Features:

- Designed as per best steam engineering practices

- Full discharge capacity of the PRS

- Ensures low noise levels

- Can be used in hazardous area

- Operates even in low flow conditions

- Quick response to pressure changes

Condensate Recovery System

Key Products Portfolio

Condensate Recovery System:

Prefabricated Modules For Main Steam Line and Header Drains Explore our ready to install prefabricated assembly comprising of thermodynamic steam trap, valves, pipes and fittings that are simpler to install.

- Thermodynamic Trap Module

- Float Trap Module

- Air Vent Module

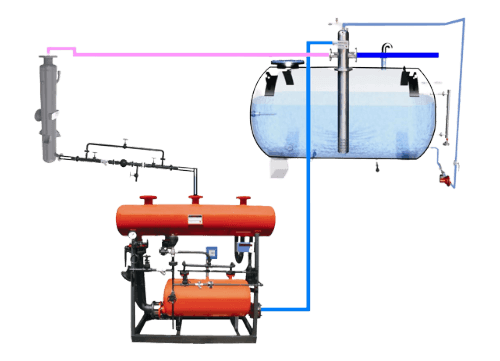

High Pressure Condensate Recovery System (HPCRS)

- 100% Condensate heat and water recovery

- No flashing at feed water tank

- Enhanced boiler operating capacity

- Eliminates steam pressure fluctuations

- Improved steam dryness fraction

- Better boiler response to varying steam demand

- Water saving by flash recovery

- Reduced scaling of boiler tubes and wetted surfaces

Thermodynamic Trap Module

- Ready to install with flanged ends

- Reduced installation time & site engineering

- Module facilitates easy maintenance

- Both IBR certified & Non IBR TD trap module available

- Can also be supplied with bellow seal valves

Float Trap Module

- Prefabricated ready to install with flanged ends

- Eliminates problem of back pressure

- Easy maintenance of steam trap and strainer cleaning.

- Designed for effective condensate recovery

- Test valve for online performance checking

Air Vent Module

- Ready to install with flanged ends

- Reduced installation time & site engineering

- Module facilitates easy maintenance of steam trap

- Recommended at highest point of steam mains and dead end of steam lines

- Both IBR certified & Non IBR available

TACTS-Rx (Thermax Automatic Condensate Transfer Pump)

- High reliability due to zero moving part

- No need of Pressure Reducing Valve/Station till 10 bar

- Discharge condensate of 25 litres/stroke

- Weatherproof IP52 & Ex-proof design option

- Skid mounted unit – easy to install

- High condensate temperature return

Process Automation

Key Products Portfolio

Rice Dryer Automation System

PLC based system providing flexibility and precise control in the temperature ramp-up cycle with varying temperature rates – meeting the requirements in paddy drying process.

Salient Product Features:

- Precise air temperature control

- Changing predefined set points without operator interference

- Proven PLC based controller system

- Excellent performance reduces rice breakage

- Reduces maintenance need, increases equipment life

PLYMax Automation System

Press automation system comprising of steam, cooling water and chilled water circuit instrumentation for plywoods and laminate industries.

Salient Product Features:

- Precise control of process parameters

- Pre-built and alarms

- A reliable PLC based controller

- Improved product quality with reduced wastage

- Reduces maintenance and downtime

- Minimised steam consumption with improved condensate recovery

Custom Solutions for Specific Customer Benefits

InstaHeat – Hot Water Generator: packaged and instantaneous hot water generator that uses steam as a heat source in a compactly designed heat exchanger.

*Subjective to state norms

Industry Agnostic Solutions - Delivering Nothing but Efficiency