INLET AIR COOLING

Improve efficiency of inlet air cooling with Thermax absorption cooling solutions. Tapping waste heat for source, the chillers are energy-efficient and sustainable means of industrial cooling

INLET AIR COOLING

Inlet Air Cooling (IAC) is a system for cooling inlet air to improve the output of gas turbines, engines and compressors in hot and humid climates. It is an established fact that turbines and compressors operate less efficiently in in hot and humid climates, due to the heat and humidity of the air intake. Higher ambient temperatures have low density of air and hence affects the performance of gas turbines and compressors.

A proper cooling system in place, cools the hot air to an optimum temperature as it enters the inlet of a gas turbine, engine or a compressor increasing efficiency and performance by utilizing the waste heat generated inside the plant. Hence, absorption cooling solutions are the perfect fit for gas turbines and compressors operators seeking to improve plant output and efficiency increase at reduced operations costs.

While inlet air cooling can be achieved by methods such as evaporative cooling, fogging and vapour compression, vapour absorption proves to be the best of all with maximum benefits and minimum shortcomings to it.

BENEFITS

- Gas turbine and compressor capacity increase between 18 % and 25 %

- Can reach lower temperatures than wet bulb, easily achieves ISO conditions

- High efficiency, even with high humidity

- Almost no electrical consumption

- Efficiently uses waste heat from the plant

- Significantly less moving parts and hence fewer maintenance

- Silent operation

To know more about the application and benefits of our solutions, contact our experts now

OUR OFFERINGS

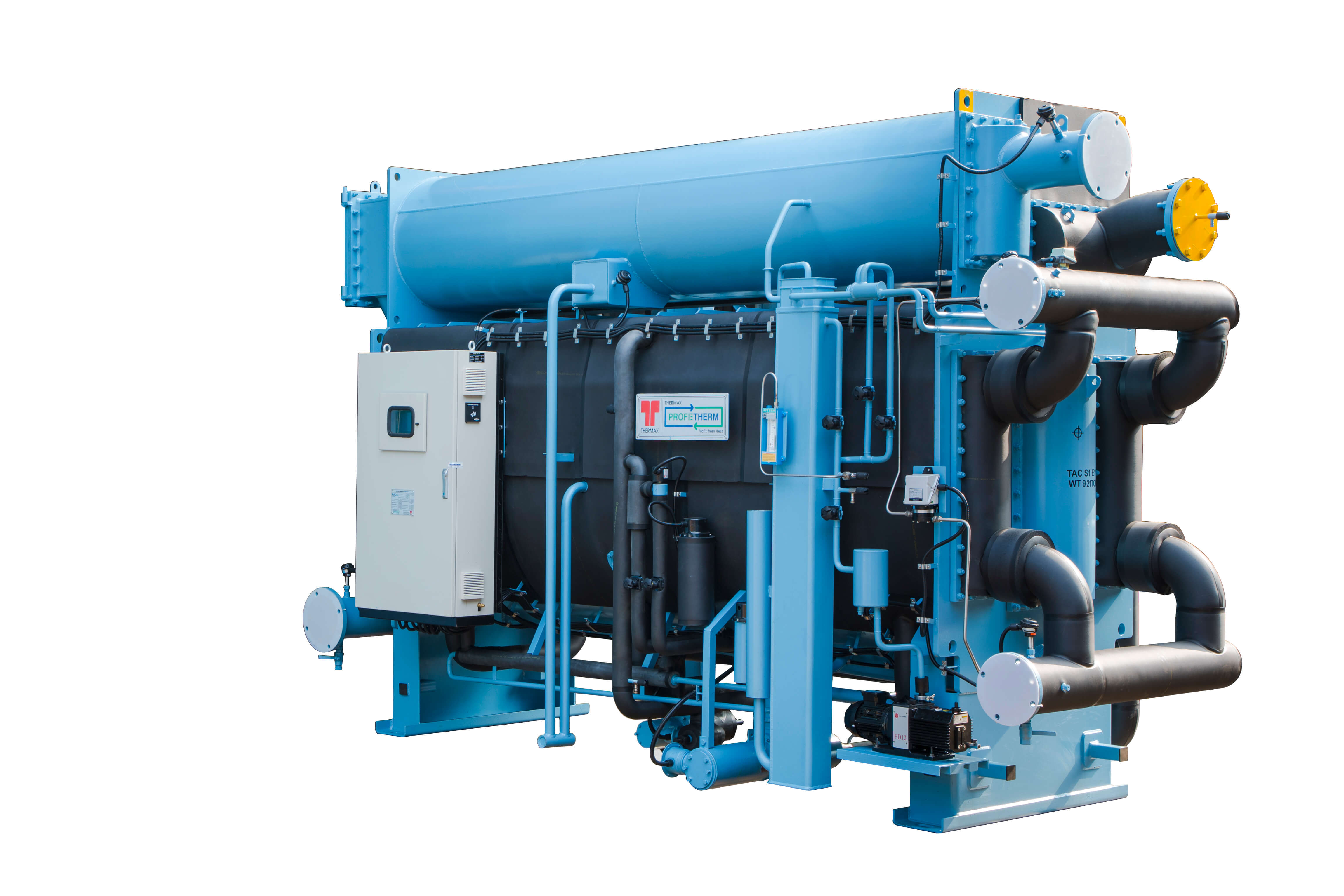

SINGLE EFFECT STEAM DRIVEN VAPOUR ABSORPTION CHILLER

Heat Source: Steam

Pressure: 0 bar.g – 3.5 bar.g

COP: 0.8

Capacity: 100 – 3500 TR

Heat energy available in the form of (LP- low pressure)

- LP vapour (0.1 bar.g, 103OC) coming from continuous polymerisation process in textile industry

- LP steam generated from potato fryer, instant noodle plant etc.

- LP Steam extraction from steam turbine in power plants

- Flash steam recovery

DOUBLE EFFECT STEAM FIRED VAPOUR ABSORPTION CHILLER

Heat Source: Steam

Pressure: 3 bar.g – 10.5 bar.g

COP: 1.5

Capacity: 50 – 3500 TR

Heat energy available in the form of

- Steam from boiler

- Steam from processes

- Steam from cogeneration plants

- Extraction from steam turbine

DOUBLE EFFECT STEAM FIRED VAPOUR ABSORPTION CHILLER

Heat Source: Steam

Pressure: 3 bar.g – 10.5 bar.g

COP: 1.5

Capacity: 50 – 3500 TR

Heat energy available in the form of

- Steam from boiler

- Steam from processes

- Steam from cogeneration plants

- Extraction from steam turbine

REFERENCES

Deepak fertilisers & petrochemicals Corp

Location: India

Chiller Type: Double effect steam driven chiller

Capacity: 270 TR

No. of machine: 1

Southern Petrochemical Industries Corporation

Chiller Type: Multi energy driven vapour absorption chiller

Location: India

Capacity: 560 TR

No. of machine: 1

Chambal fertilizer

Location: India

Chiller Type: Double effect steam driven chiller

Capacity: 2030 TR

No. of machine: 1

Gujarat state fertilizers & chemicals Ltd

Location: India

Chiller Type: Single effect steam driven chiller

Capacity: 445

No. of machine: 1