Thermeon 2.0 is an advanced, compact, and fully packaged steam generator designed to meet the steam needs of micro, small and medium enterprises (MSMEs). Building on the success of its predecessor that was launched in 2014, the new Thermeon 2.0 brings enhanced capacity range, improved combustion efficiency and a greater operational reliability. This multi-fuel flexible boiler is an ideal solution for industries looking for an affordable, safe and efficient source of process steam.

STEAM BOILERS

Thermax offers coil type steam boilers in the range of 50 to 850 kg steam per hour. The coil type boiler generates steam instantly and is extremely easy to install and commission. These boilers are safe, reliable and designed to operate on a wide range of liquid and gaseous fuels including heavy oil, light oil, gas, and dual fuel options.

Products

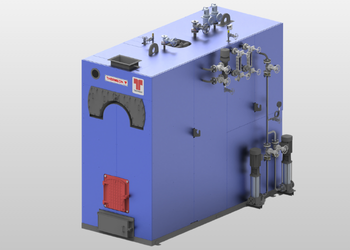

Thermeon 2.0

Product Features

- Enhanced combustion efficiency with dual furnace technology, offering increased furnace volume

- Multi-fuel flexibility compatible with biomass briquettes, cashew nut shells, biomass pellets, wood, and Indonesian coal

- Quick steam generation enabled by high water hold-up for faster response

- High combustion efficiency and low emissions achieved with a multi-combustor design and advanced stationary grate combustor

- Reliable performance with durable triplex grate bars and high-quality components

- Space-saving and easy installation with a compact design requiring minimal site work

- Safety and compliance with IBR standards, including a user-friendly access port for ergonomic maintenance

- Fully packaged and ready to install with pre-assembly and pre-insulation for convenience

Operating Range

- Steam output: 0.3 TPH to 2 TPH

- Standard design pressure: 7 kg/cm² g and 10.54 kg/cm² g

- Thermax’s Biomass boiler commissioned at Serum Institute is a boon for saving the environment and reducing fuel cost by 30%

- Thermax successfully commissioned a steamboiler at Govind dairy Phaltan

- Thermax succesfully commissioned a biomass boiler for an FMCG major in India

- Thermax process heating solutions reduced carbon footprint- the plant is equivalent to carbon capture by 3 lakh trees!

- Thermax made it possible! Upto 45% fuel cost saving using 100% biomass firing

- Thermax sets a record by commissioning a 40 TPH boiler in just 40 days for Pharmaceutical major in Indonesia

- Thermax helps Budhani Bros Waferwala to save fuel cost by 20%