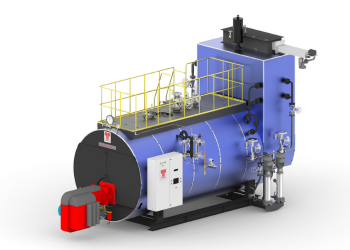

The Shellmax Global Ultra series is a smoke-tube, three-pass boiler, tailored for oil/gas firing. Designed to deliver high efficiency, reliability and flexibility, this advanced boiler is equipped with state-of-the-art burner management systems and heat recovery technologies. Featuring robust construction and thoughtfully engineered configurations, it ensures compatibility with a variety of industrial heating needs while adhering to global standards. With enhanced automation and IIoT capabilities, the Shellmax Global Ultra provides users with real-time monitoring, energy efficiency insights, and maximum operational uptime, making it the ideal choice for industries focussed on sustainability and performance.

STEAM BOILERS

Thermax offers coil type steam boilers in the range of 50 to 850 kg steam per hour. The coil type boiler generates steam instantly and is extremely easy to install and commission. These boilers are safe, reliable and designed to operate on a wide range of liquid and gaseous fuels including heavy oil, light oil, gas, and dual fuel options.

Products

Shellmax Global Ultra

Product Features

- Extended lifespan and strength with a liberally sized corrugated furnace designed to withstand high thermal stress

- Enhanced heat recovery using innovative technologies like Effimiser™ and Dewtherm™

- Compatible with Dualbloc and Monobloc burners for precise air-to-fuel ratio control, optimised combustion and reduced emissions

- Plug-and-play skid-mounted design with factory-insulation for easy installation

- Lower fuel consumption and better part-load efficiency with IE3 motors and advanced burner technology

- Maximised steam generation efficiency with EcoBoost and EffiGain systems with, real-time efficiency diagnostics

- Optimal operational control offering real-time monitoring and data logging with Thermowiz™ Nxt

- Remote monitoring and diagnostics to improve efficiency and uptime through EDGE™ Live, Thermax’s IIoT solution

Operating Range

- Capacity: 1 TPH to 16 TPH, customisable up to 34 TPH

- Design pressure: Standard design pressure of 10.54/17.5 kg/cm² (g), customisable up to 35 kg/cm² (g)

- Thermax’s Biomass boiler commissioned at Serum Institute is a boon for saving the environment and reducing fuel cost by 30%

- Thermax successfully commissioned a steamboiler at Govind dairy Phaltan

- Thermax succesfully commissioned a biomass boiler for an FMCG major in India

- Thermax process heating solutions reduced carbon footprint- the plant is equivalent to carbon capture by 3 lakh trees!

- Thermax made it possible! Upto 45% fuel cost saving using 100% biomass firing

- Thermax sets a record by commissioning a 40 TPH boiler in just 40 days for Pharmaceutical major in Indonesia

- Thermax helps Budhani Bros Waferwala to save fuel cost by 20%