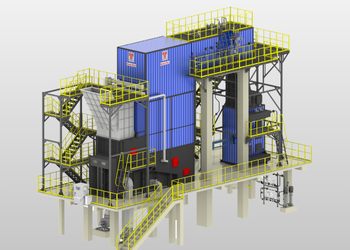

GreenPac is an advanced biomass-fired boiler engineered for high-efficiency steam generation from challenging low-density biomass fuels like rice and mustard straw. Designed for industrial applications, this boiler delivers superior performance while promoting sustainability. With standardised balance of plant offerings, GreenPac embodies Thermax’s environmentally-conscious innovation, combining reliable operation with state-of-the-art technology to meet the rising industry demand for clean energy solutions.

STEAM BOILERS

Thermax offers coil type steam boilers in the range of 50 to 850 kg steam per hour. The coil type boiler generates steam instantly and is extremely easy to install and commission. These boilers are safe, reliable and designed to operate on a wide range of liquid and gaseous fuels including heavy oil, light oil, gas, and dual fuel options.

Products

GreenPac

Product Features

- Efficient use of low-density and difficult to combust biomass fuels in as-is form, for eg. rice and mustard straw

- Universal BioGrate combustion technology offers universal biomass fuel flexibility

- Optimised combustion and heat transfer in a fully-sealed membrane panel assembly for maximum efficiency

- Enhanced system efficiency with an economiser that captures waste heat from flue gases to preheat the thermic fluid

- Higher uptime with automated cleaning through the Danblast soot-blowing system using advanced Danish technology to prevent soot buildup

- User-friendly and ergonomic design with a pre-engineered balance of plant for safe operation

- Low-emission design to minimise carbon footprint in line with global environmental standards

- Compact, modular structure for easy installation and robust performance in space-constrained industrial setups

- Thermowiz™ Nxt control system offers real-time monitoring, advanced reporting, and data logging for optimal operational control

- Enabled with EDGE Live, an IIoT solution for remote monitoring, and diagnostics to improve efficiency and uptime

Operating Range

- Capacity: 5 TPH to 16 TPH

- Operating pressure: 17.5 kg/cm2, customisable up to 21 kg/cm2

- Thermax’s Biomass boiler commissioned at Serum Institute is a boon for saving the environment and reducing fuel cost by 30%

- Thermax successfully commissioned a steamboiler at Govind dairy Phaltan

- Thermax succesfully commissioned a biomass boiler for an FMCG major in India

- Thermax process heating solutions reduced carbon footprint- the plant is equivalent to carbon capture by 3 lakh trees!

- Thermax made it possible! Upto 45% fuel cost saving using 100% biomass firing

- Thermax sets a record by commissioning a 40 TPH boiler in just 40 days for Pharmaceutical major in Indonesia

- Thermax helps Budhani Bros Waferwala to save fuel cost by 20%