FOOD PROCESSING

Benefit from up to 40% operational savings by deploying Thermax cooling and heating solutions, catering to sectors from dairy to beverages

DAIRY PROCESSING

Modern processing equipment in the dairy industry account for about 40% of its total energy consumption. Thermax cooling and heating machines, when employed for chilling, pasteurization, and storage

EDIBLE OIL

Edible oil undergoes intensive refining phases before the final product is synthesized. The line includes cleaning of the seeds, preheating, flaking, conditioning

COCONUT PROCESSING INDUSTRY

Coconuts are processed for various products such as water, milk, cream, oil and more. Coconut processing industries require advanced cooling technologies

PROCESSING AND PRESERVING FRUIT JUICE

Fruit pulp processing is a fast-growing industry owing to the increased consumer preference for healthy food. In the process of making regional fruits available all over the globe

ICE CREAM MANUFACTURING

Freezing is the most important process in ice cream manufacturing. The quality of the end product mainly depends upon the efficiency of the freezer system. The cold chain systems add up largely

To know more about the application and benefits of our solutions, contact our experts now

OUR OFFERINGS

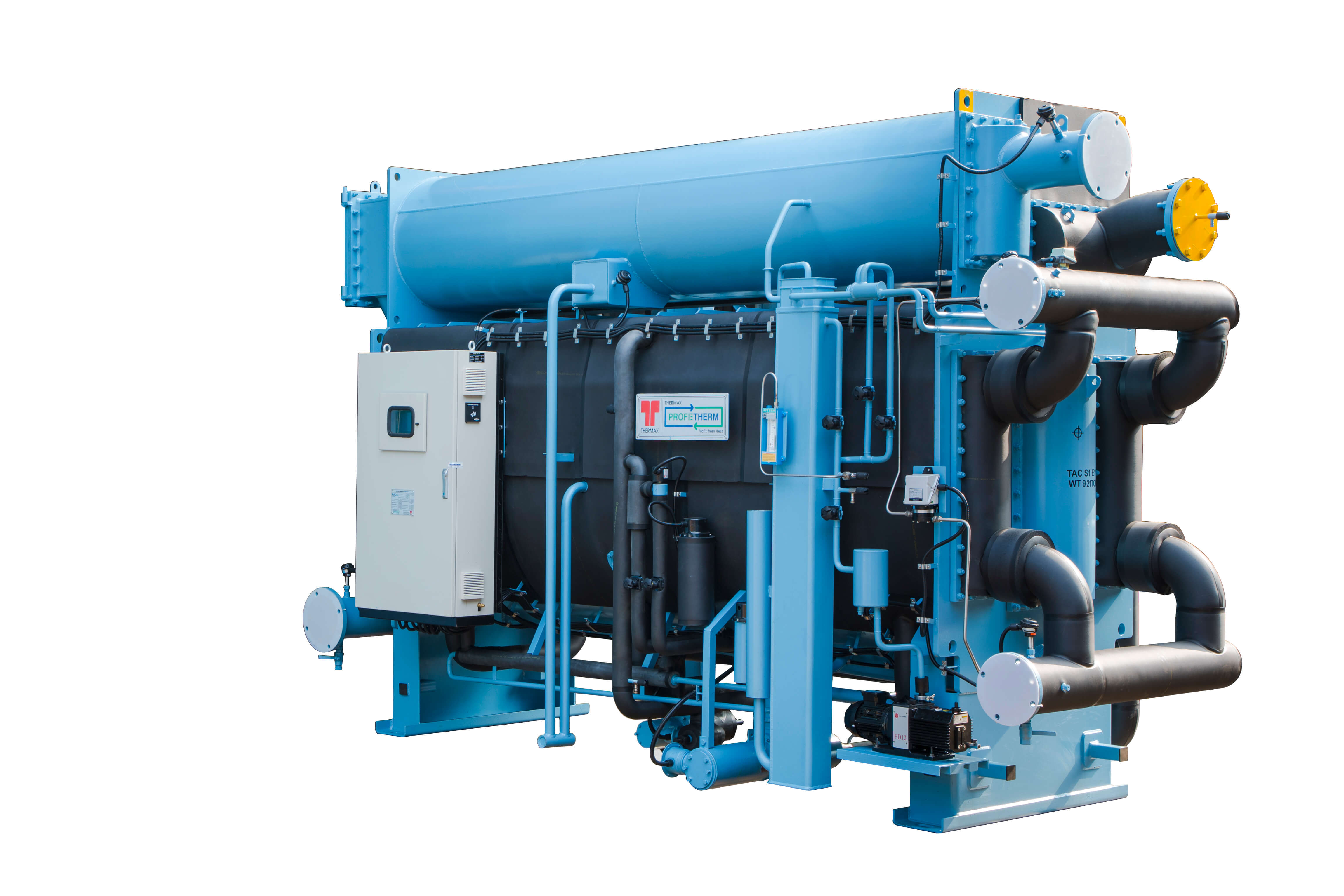

SINGLE EFFECT STEAM DRIVEN VAPOUR ABSORPTION CHILLER

Heat Source: Steam

Pressure: 0 bar.g – 3.5 bar.g

COP: 0.8

Capacity: 100 – 3500 TR

Heat energy available in the form of (LP- low pressure)

- LP vapour (0.1 bar.g, 103OC) coming from continuous polymerisation process in textile industry

- LP steam generated from potato fryer, instant noodle plant etc.

- LP Steam extraction from steam turbine in power plants

- Flash steam recovery

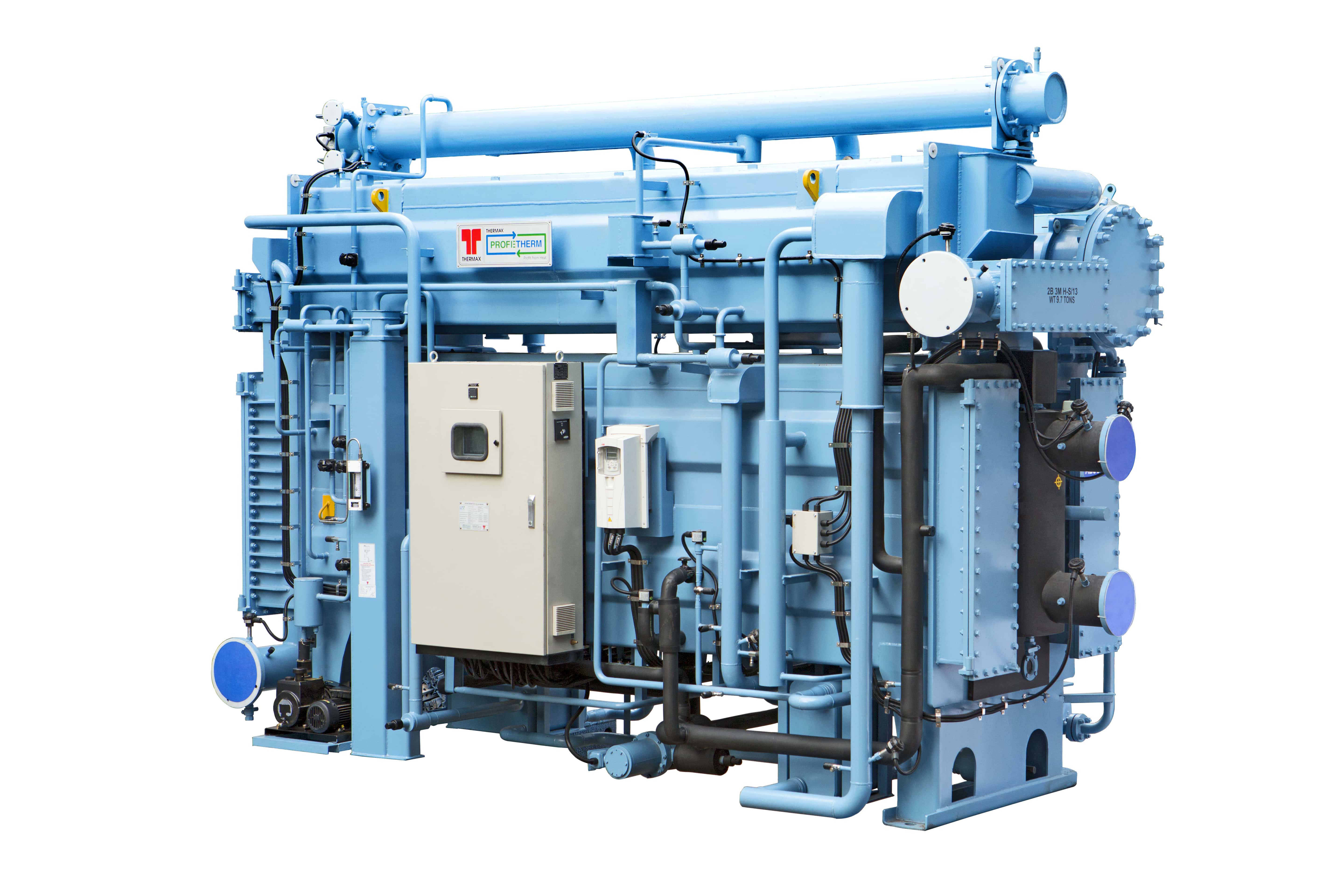

DOUBLE EFFECT STEAM FIRED VAPOUR ABSORPTION CHILLER

Heat Source: Steam

Pressure: 3 bar.g – 10.5 bar.g

COP: 1.5

Capacity: 50 – 3500 TR

Heat energy available in the form of

- Steam from boiler

- Steam from processes

- Steam from cogeneration plants

- Extraction from steam turbine

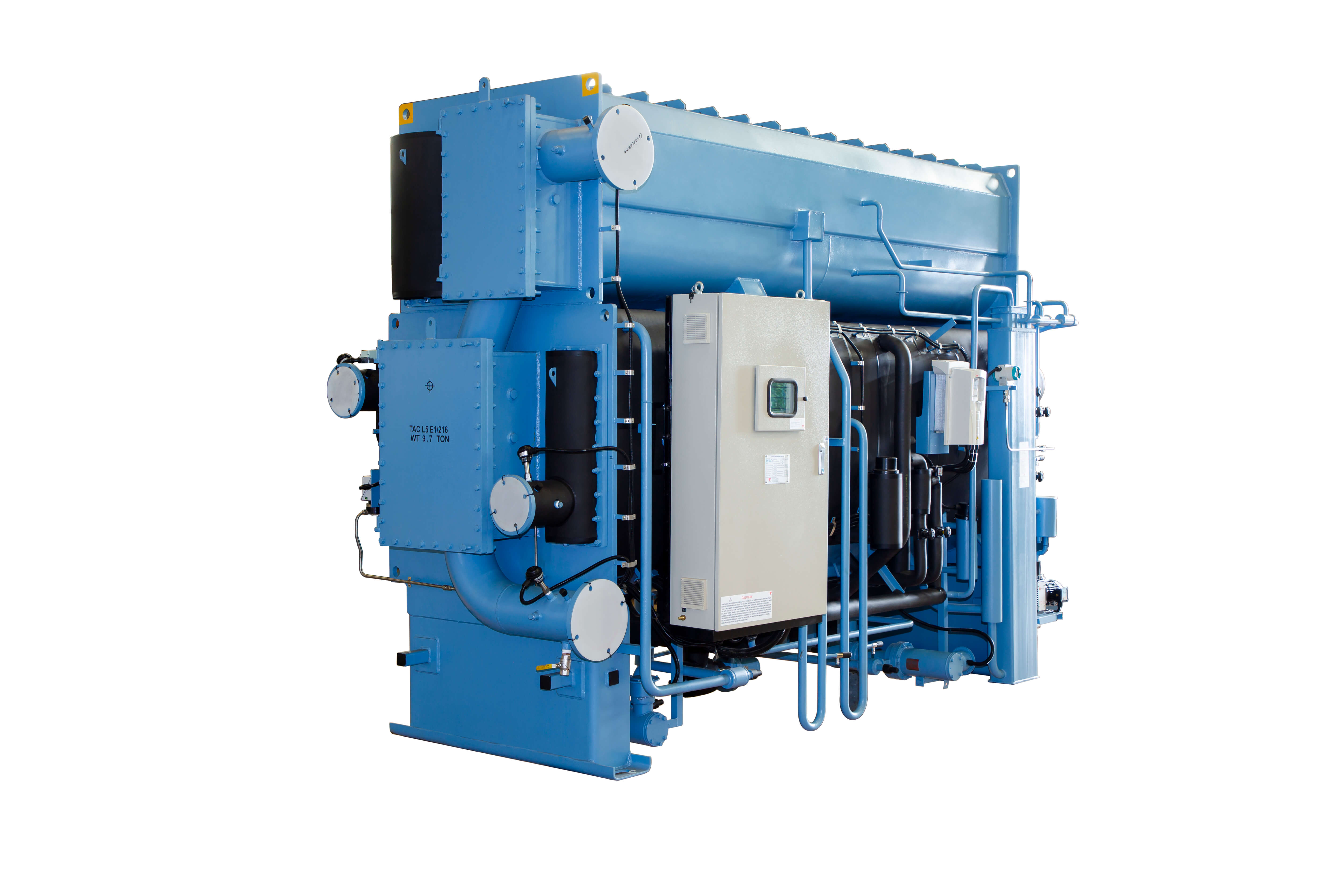

DOUBLE EFFECT STEAM FIRED VAPOUR ABSORPTION CHILLER

Heat Source: Steam

Pressure: 3 bar.g – 10.5 bar.g

COP: 1.5

Capacity: 50 – 3500 TR

Heat energy available in the form of

- Steam from boiler

- Steam from processes

- Steam from cogeneration plants

- Extraction from steam turbine

SINGLE EFFECT LOW TEMPERATURE HOT WATER DRIVEN VAPOUR ABSORPTION CHILLER

Heat Source: Hot Water

Inlet water temperature: 80OC – 120OC

COP: 0.8

Capacity: 180 – 1650 TR

Heat energy available in the form of

- Engine jacket water

- Hot water from solar collectors

- Process condensate

- Flue gas recovery from incinerators

- Process heat recovery

- Fuel cells

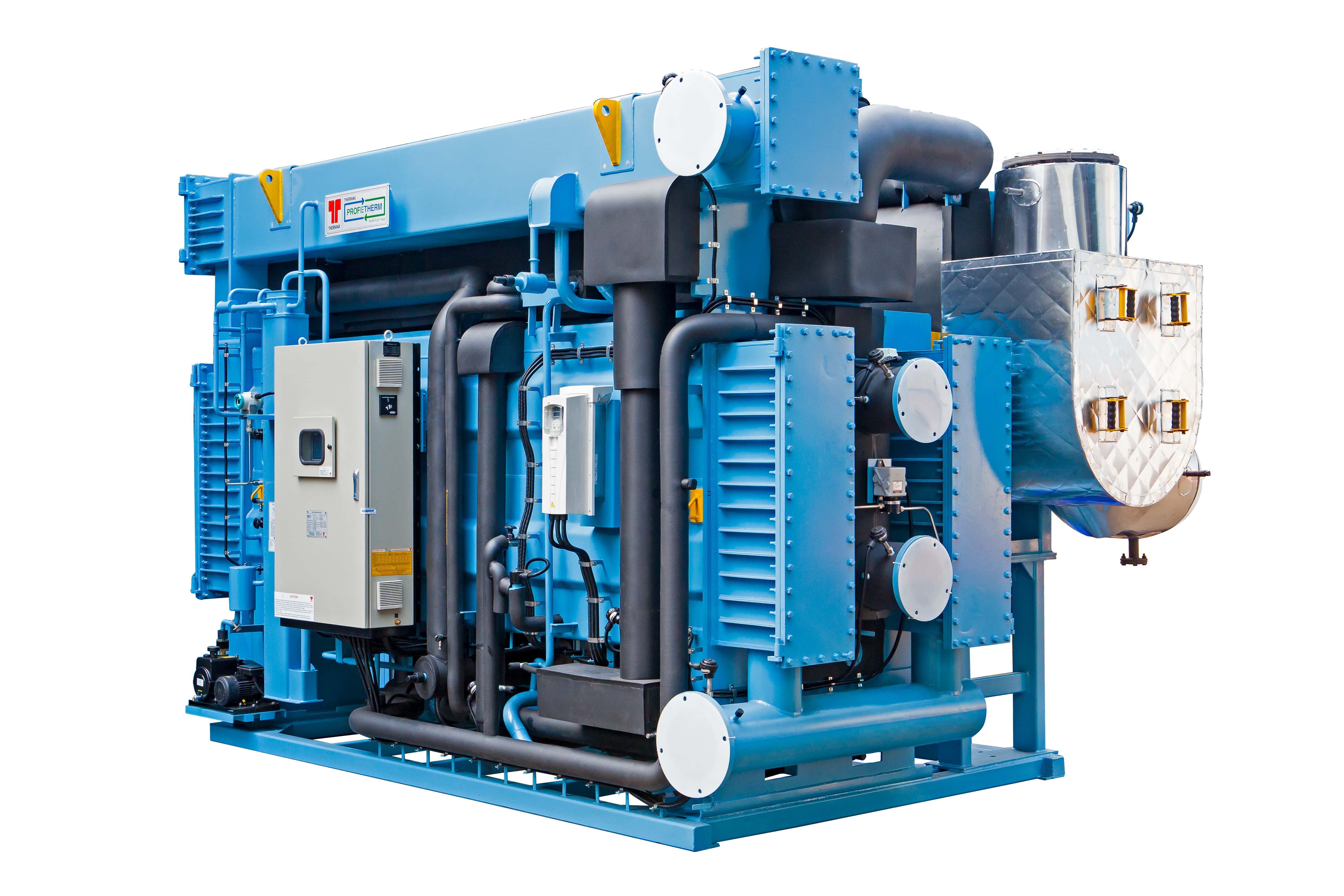

DOUBLE EFFECT DIRECT FIRED ABSORPTION CHILLER

Heat Source: Direct Fuel Firing

COP: 1.5

Capacity: 50 – 3000 TR

Heat energy available in the form of

- Natural gas

- LPG

- Propane

- Town gas

- Kerosene

- High speed diesel

- Oil

- Biogas

DOUBLE EFFECT DIRECT FIRED ABSORPTION CHILLER

Heat Source: Direct Fuel Firing

COP: 1.5

Capacity: 50 – 3000 TR

Heat energy available in the form of

- Natural gas

- LPG

- Propane

- Town gas

- Kerosene

- High speed diesel

- Oil

- Biogas

DOUBLE EFFECT EXHAUST FIRED ABSORPTION CHILLER

Heat Source: Exhaust Gas

Inlet Temperature: 250OC – 600OC

COP: 1.5

Capacity: 50 – 3500 TR

Heat energy available in the form of

- Flue gas from gas engines or diesel engines

- Flue gas from gas turbines

- Flue gas from micro turbines

- Flue gas from fuel cells

- Clean Flue gas from ovens, furnaces, thermic fluid heaters etc.

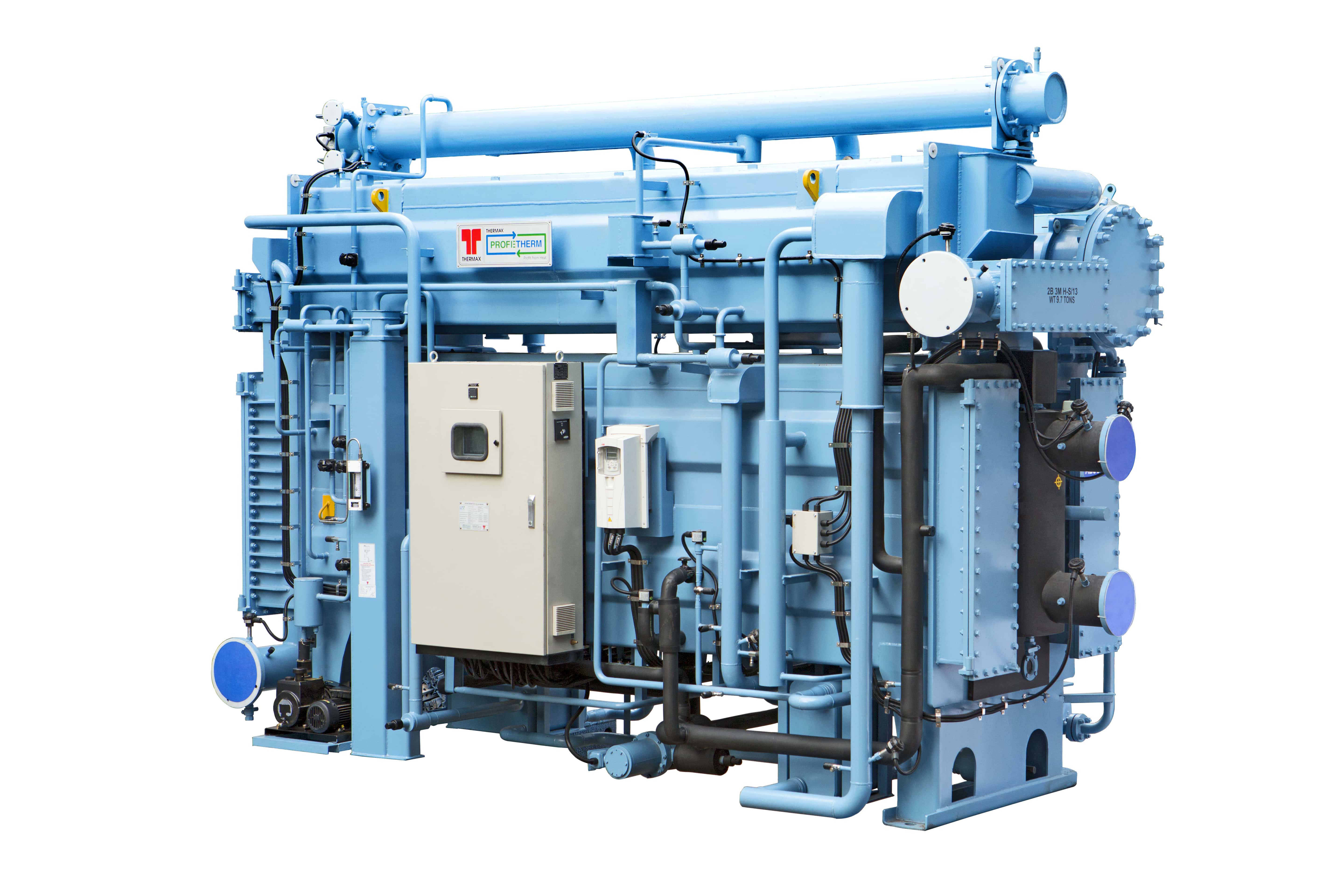

HIGH EFFICIENCY CHILLER – HEATER

Heat Source: Steam, Hot Water, Direct Fuel Firing & Exhaust Gas

Capacity:

Cooling : 100 – 3500 TR

Heating : 100 Kw – 9 MW

Heat energy available in the form of

- Dry saturated steam – 3.0 – 10.0 bar.g

- High temperature hot water -145 – 180OC

- Direct fuel firing – Gas / Oil / LPG / Propane)

- Exhaust gas (275 – 600OC)

HIGH EFFICIENCY CHILLER – HEATER

Heat Source: Steam, Hot Water, Direct Fuel Firing & Exhaust Gas

Capacity:

Cooling : 100 – 3500 TR

Heating : 100 Kw – 9 MW

Heat energy available in the form of

- Dry saturated steam – 3.0 – 10.0 bar.g

- High temperature hot water -145 – 180OC

- Direct fuel firing – Gas / Oil / LPG / Propane)

- Exhaust gas (275 – 600OC)

HYBRID CHILLER

Heat Source: Steam, Hot Water & Exhaust Gas

Capacity: 50 – 250 TR

BRINE TEMPERATURE: -5 to -25OC

Heat energy available in the form of

- Dry saturated steam (0.5 – 3.5 bar.g)

- Dry saturated steam (5.0 – 10.5 bar.g)

- Low temperature hot water (90 – 150OC)

- High temperature hot water (150 – 180OC)

- Exhaust gases (300 – 600OC)

EVAPORATIVE CONDENSER

Product Features

- Replacement product against conventional systems (atmospheric condenser, shell & tube heat exchanger + cooling tower, plate heat exchanger + cooling tower)

- For ammonia/freon condensation at lower temperature

- Ideal for various refrigeration systems and climatic conditions

- Compatible with all types of refrigeration compressors i.e. reciprocating, screw, scroll, rotary and centrifugal

- Combined and counter flow technology available

- Modular construction allows plug & play installation for new and replacement units

Product Capacity: 50 TR and above

Capacity: 20 m3/h onwards

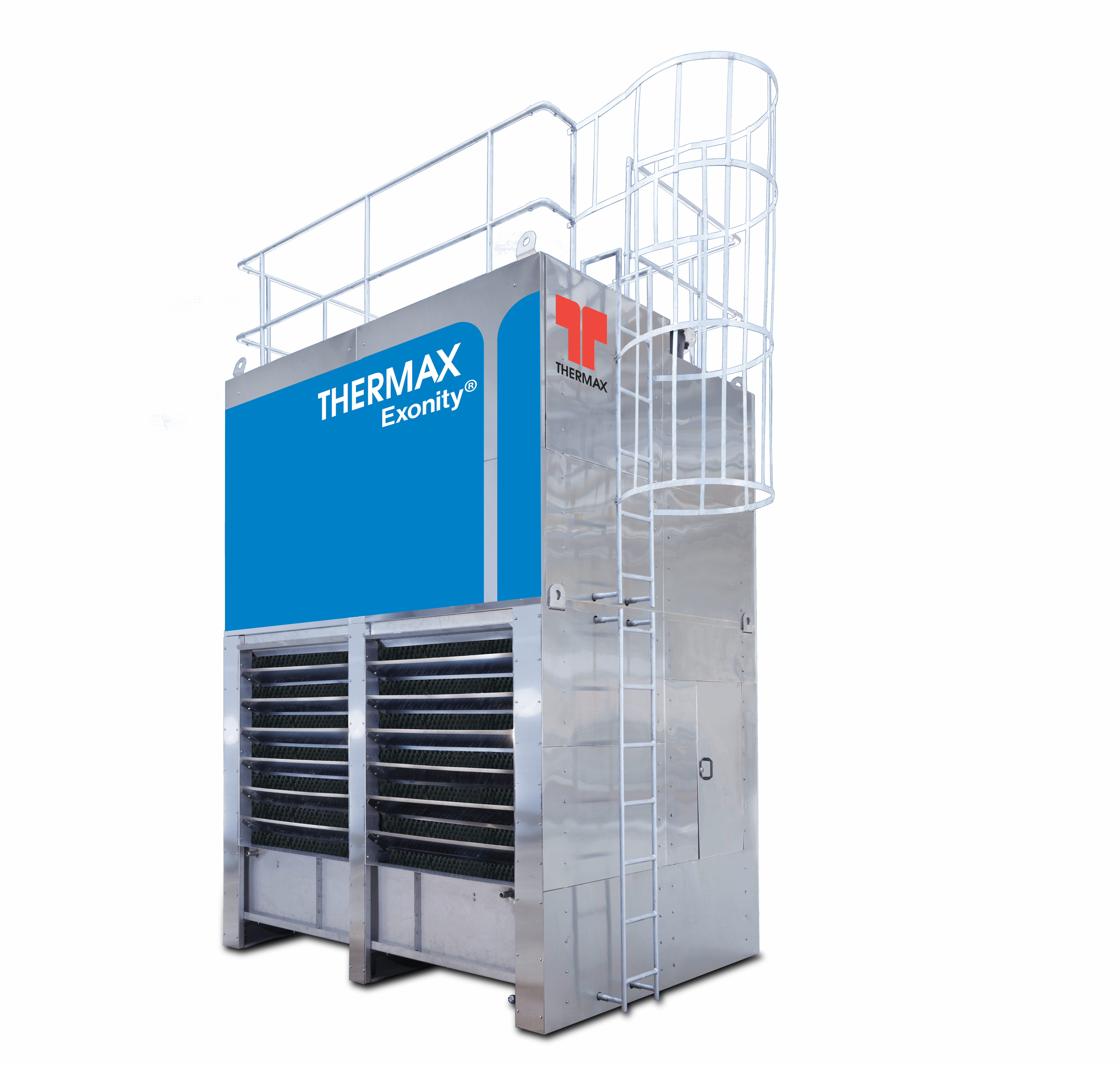

CLOSED LOOP COOLING TOWER

Product Features

- Can be operated for higher temperature difference (Δ T)

- Zero contamination due to closed loop

- 100% Water savings in exhaust steam condensing

- Low Maintenance Costs

- Lesser environmental impact due to the elimination of water los

Capacity: 20 m3/h onwards

REFERENCES

Hatsun Agro Product Ltd

Dairy

Location: India

Type: Double effect steam fired absorption chiller

Capacity: 300 TR

Asia Pacific Oil Manufacturing Corp

Edible Oil

Location: Philippines

Type: Double effect steam fired absorption chiller

Capacity: 40 TR

Tipco Foods

Fruit Pulp & Juice

Location: Thailand

Type: Double effect steam fired absorption chiller

Capacity: 500 TR

Ghana Speciality Fats Industries Ltd

Edible Oil

Location: Ghana

Type: Double effect steam fired absorption chiller

Capacity: 300 TR

Mueller Foods

Dairy

Location: United Kingdom

Type: Low temperature hot water driven chiller

Capacity: 113.75 TR

Heinrichstahler Milchwerke

Dairy

Location: Germany

Type : Double-effect steam fired absorption chillers

Capacity :600 TR

PT Kalimantan Kelapa Jaya

Coconut processing

Location: Indonesia

Type: Double effect steam fired absorption chiller

Capacity: 250 TR

Heritage Foods Ltd

Location: India

Type: Evaporative Condensers

Capacity: 300 TR

CP Milk

Dairy

Location: India

Type: Evaporative Condenser

Capacity: 500 KW