A global energy transition is underway, and India is making steady progress towards a greener, more sustainable future. While the discourse on renewable energy centers around solar and wind power, it has become apparent that we also need to find clean and efficient fuel alternatives for industrial processes, transportation, and households. India needs to adopt a multi-fuel strategy to drive socioeconomic growth and sustainable development, and Thermax is well-positioned to help commercial and industrial establishments do exactly that.

Thermax, with its integrated energy and environment solutions, is helping India unlock the energy potential of Bio-CNG, Green Hydrogen, coal gasification, waste-to-energy, and waste heat recovery. Enabling the energy transition calls for the collective efforts of stakeholders across multiple sectors. Cognizant of the importance of policy alignment and industry participation, Thermax collaborates with farmers, municipal bodies, businesses, and other concerned stakeholders to commercialise the production of clean fuels. The company offers technologies, solutions, and services to support the multi-fuel strategy it champions.

Biofuels, such as Bio-CNG: India’s agriculture sector generates hundreds of tonnes of crop residue and biomass every year, which can be used to produce biofuels. Compressed biogas, or bio-CNG, is one of them. Its calorific value and other qualities are similar to those of compressed natural gas (CNG). Both agricultural waste and municipal waste can serve as raw material for bio-CNG production. CNG-powered vehicles can run on bio-CNG without any change in design. In rural areas, bio-CNG can power tractors and other agricultural equipment. Thermax’s offerings in the bioenergy space include Bioenergen, an advanced and highly efficient organic biodegradable waste processing plant that produces high-yield biogas. The residue can be used as nutrient-rich fertilizer. Meanwhile, Thermax Onsite Energy Solutions Limited – our wholly owned subsidiary – manages the supply chain of various biofuels across India.

Green Hydrogen: With applications spanning energy storage, emission control, and transportation, Green Hydrogen is a versatile and clean energy solution. Thermax recently ventured to explore green hydrogen projects, including new manufacturing facilities, in India. Thermax is also aligned to the Indian government’s National Green Hydrogen Mission and ammonia/hydrogen policies.

Coal Gasification: Thermax believes that coal gasification has great potential to strengthen India’s energy security and reduce foreign exchange outflow. India has the fourth-highest coal reserves in the world, albeit with higher ash content. To address this challenge, Thermax collaborated with IIT Delhi to develop a gasification technique suitable for Indian coal. Their efforts yielded a state-of-the-art gasifier conceptualised, designed, and installed in Pune. With it, the syngas or flue gas produced from coal gasification can be utilised to produce ethanol, methanol, and various downstream chemicals. Thermax aims to bring this technology up to commercial scale.

Waste to Energy: Thermax’s waste-to-energy initiatives transform waste materials into valuable energy resources, thus promoting a circular economy and contributing to energy security. One such project, in collaboration with a German customer, has received the prestigious ‘German Renewables Award’. It involves converting 320,000 tonnes of waste into energy through controlled incineration. The initiative saves over 100,000 tonnes of CO2 and supplies almost 10 percent of Hamburg’s district heating needs.

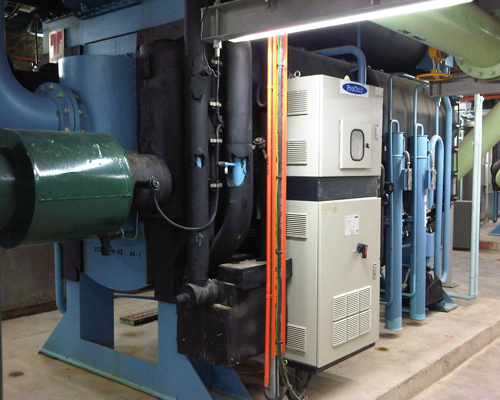

Waste Heat Recovery: Thermax provides equipment and steam generation solutions encompassing the combustion of different solid, liquid, and gaseous fuels, and the recovery of heat from turbine/engine exhaust and industrial processes. With its steam boilers, thermal oil heaters, hot water generators, thermosyphons, waste heat recovery units, Thermax optimizes energy consumption and improves overall industrial efficiency. All these outcomes are in line with India’s national goals of minimizing energy waste and promoting sustainable industrial practices.

With its strong commitment to pioneering clean technologies and responsible practices, Thermax’s business goals are aligned to India’s energy transition goals. The company continues to work closely with its customers and technology partners to help industries minimize their environmental impact. A multi-fuel approach will accelerate progress in this direction and go a long way towards powering sustainable growth for our businesses, people, and country.