The scenario

Digital transformation has occupied the centre stage in the recent past and has started reshaping the way manufacturing sector works. The recent wave of lockdowns that followed the COVID outbreak accelerated the pace of digital transformation. Some enterprises were prepared on how to deal with it, some learnt it on the go, and some are still learning.

As a key enabler of our growth ambitions and vision of becoming a high performance global organisation, we at Thermax commenced our ‘Smart journey’ with a structured digital roadmap. We have been progressively adopting digital tools to improve our business efficiency, adapt to a more agile and connected way of working; all this is backed by strong data security. Our digital transformation journey consists of three pillars – from individualistic to collaborative for the organisation, from people-driven to industry benchmarked processes and from a product-based approach to outcome-oriented solutions for customers to ensure precision, reliability and consistency.

Manufacturing competitiveness

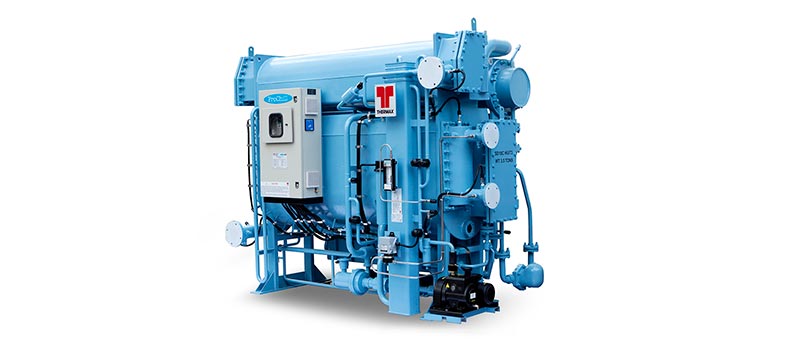

The first major milestone in the journey was the commissioning of a state-of-the-art manufacturing facility at Sri City, Andhra Pradesh for manufacturing high efficiency vapour absorption chillers for global markets. The factory deploys high level of automation, a first of a kind for a capital goods company, equipped with an automated MES (Manufacturing Execution System) and skilled workforce on the shop floor.

Employee collaboration

We aim to adopt contemporary practices that can integrate all operations and transform business processes into more strategic and measurable ones. The HR team at Thermax launched SAP SuccessFactors, which is an industry-leading cloud human capital management (HCM) suite that uses advanced technologies and helps in managing various facets of employees’ organisational lifecycle. This covers core HR and payroll, attendance management and time logs, performance and appraisals, recruitment and onboarding, learning and development; with a focus on people engagement and experience.

Digitalisation is also keeping finances in order, which is another daunting task. Now imagine, for claiming expenses you have to fill a form, get it approved by your manager and then collate all the physical copies of the bills and submit them to your finance team. Isn’t a tedious task? With the help of SAP Concur,

claiming paperless expense has become so much easier and productive for employees, managers and the finance team.

The latest addition to the digital platform is THERMSafe, which was launched during the ongoing pandemic crisis. It is an app developed in-house to capture the health status of employees while they are working from home and before entering the office premises. The advanced feature in the application prompts users to be self-quarantined if needed and also update them on sanitisation status being followed at office premises and common areas.

Customer engagement

Thermax has been leveraging digitalisation to make the company more efficient; moreover enhance the value of our offerings for our customers. Recently, Thermax commissioned a large auxiliary boiler online for a customer in Egypt with the help of various tools, including TeamViewer, Microsoft Teams, Grafana Portal, among others, that enabled real-time collaboration between two teams located in different countries.

According to a study by Gartner, the IoT market will grow to 5.8 billion in 2020. Like other companies, Thermax is also exploring ways in which it can inculcate IoT enabled solutions in its business offerings. Thermax’s industrial analytics solution provider, Ultramind, is IoT enabled and can be integrated with boilers and heaters that has PLC systems of any make. It identifies gaps in operating parameters, analyse factors and make necessary recommendations to improve combustion and heat transfer processes. The tool is a great value addition for customers in terms of improving efficiency, safety standards, seamless maintenance, and critical spare parts planning.

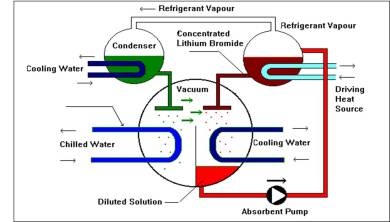

Thermax’s Remote Online System Support (ROSS) is a cloud-based remote monitoring technology, which monitors and controls the performance of absorption chillers across the globe, thus offering better customer service and chiller maintenance remotely. The advanced feature supports in managing and monitoring the chillers with alarms, trend graphs, and reports efficiently. ROSS is now connected to around 547 chillers across the globe.

Concurrent to improving customer facing application, Thermax is also enhancing its internal processes to provide the best quality output to its customers. We have deployed a robust automated proposal generation process, addressing customer requirements accurately with the shorter response time. The digital engineer-to-order process supports advanced engineering calculations and functions and seamlessly integrates design softwares with customer needs to streamline the automatic generation of technical proposals, engineering drawings and BOQs.

Through our digitalisation initiatives, our endeavour is to create a connected ecosystem where we engage our customers seamlessly and provide better customer experience, regardless of time and place.