Humans have heavily relied on fossil fuels for far too long to meet their energy demands, impacting the environment adversely and ushering in a plethora of issues ranging from climate change to deterioration in air quality.

As of today, human activities have triggered global temperatures to rise by about 1 degree Celsius above pre-industrial levels (1950-1900). Record pollution levels are causing a paradigm shift in climatic conditions, and governments around the world are trying to stop the disastrous effects of climate change.

Green Energy – Need of the Hour

The problems caused by the use of fossil fuels can be solved by using renewable energy. Renewable energy resources are clean, inexhaustible, and environmentally conservative forms of energy that are harnessed from sources that are naturally replenished. They are much different from fossil fuels principally in their diversity, abundance, and potential for use anywhere on the planet. These sources are infinite and inexhaustible, but above all, they do not emit greenhouse gases – which cause climate change. There has been a global impetus on clean energy implementation with government incentives, encouraging industries to opt for clean power. They are feasible energy sources due to low lifecycle cost in comparison to fossil fuels that are increasing quite steeply on the back of global demand and volatility in the market.

Renewable energy includes sources such as sunlight, wind, rain, tides, and geothermal heat. According to the International Energy Agency (IEA), renewable energy sources represented nearly half of all new electricity generation capacity installed in 2014. Renewables constituted the second biggest source of electricity worldwide, behind coal.

Advantages of Adopting Clean Energy

Clean energy sources also provide a unique advantage to local economies because of their abundance in nature. Unlike the restrictive nature of fossil fuels, renewable energy sources are present everywhere in the world – whether in the form of wind, sun, water, or biomass, for countries to produce clean energy.

Renewables, specifically solar and wind, are more viable than their conventional counterparts. They are the most economically efficient way to generate electricity in a growing number of markets. Renewable energies are fast becoming the most sustainable solution not only environmentally but also economically for a better future.

Leading the Transition to Green Energy

Since 1980, Thermax has been focussed on sustainable energy and environmental solutions. It has developed several innovative technologies and unique offerings in clean energy, which are more pronounced today with an increased focus on climate change and are in line with the COP26 agreement. Thus Thermax has a long history of extensive engagement with diverse sectors and tie-ups with technology majors, which has empowered the group to deliver unmatched solutions to its clientele.

Thermax’s offerings in waste heat recovery, biofuels, solar, bio-CNG, waste to energy etc., show their commitment towards delivering clean energy. Thermax continuously introduces and innovates environment-friendly and carbon-neutral solutions capable of replacing most fossil fuels with commercial benefits, also helping us achieve Sustainable Development Goals (SDGs).

Thermax’s Renewable Energy Solutions

Solar Energy

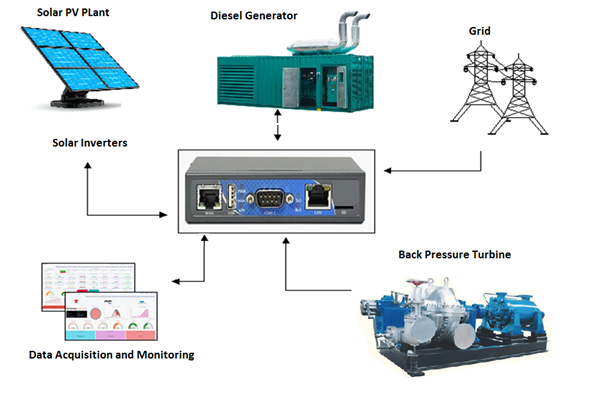

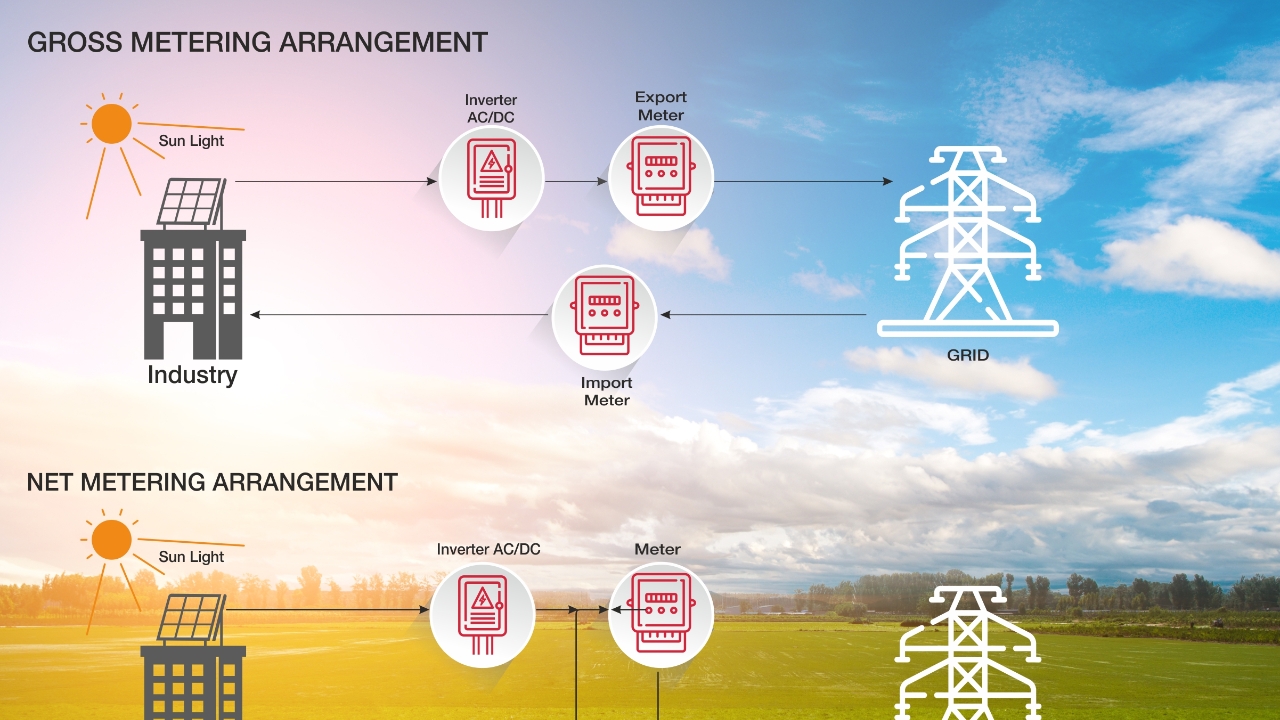

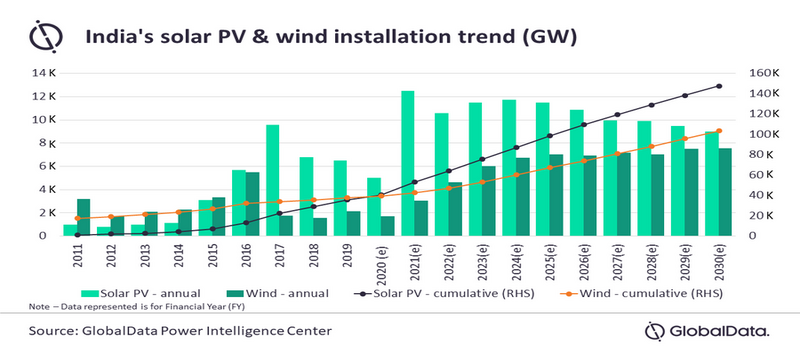

With solar PV installations spread across industries and geographies, Thermax is helping customers generate green energy and minimise electricity costs. Thermax’s solar PV solutions reinforce the brand’s reputation in offering clean energy solutions trusted by organisations across Asia, South East Asia, the Middle East, and Africa.

Solar Rooftop

Solar energy offers an excellent return on investment while utilising the rooftop space of the customer’s facility. Solar rooftop solutions can generate free electricity for more than 25 years, resulting in substantial savings and carbon footprint reduction.

Solar Ground Mounted

Thermax has an excellent track record in the installation of ground-based solar power projects. Ground-mounted solar installations deliver unbeatable ROI during the lifecycle of the project, taking the customer’s manufacturing facility towards self-reliance for its power needs.

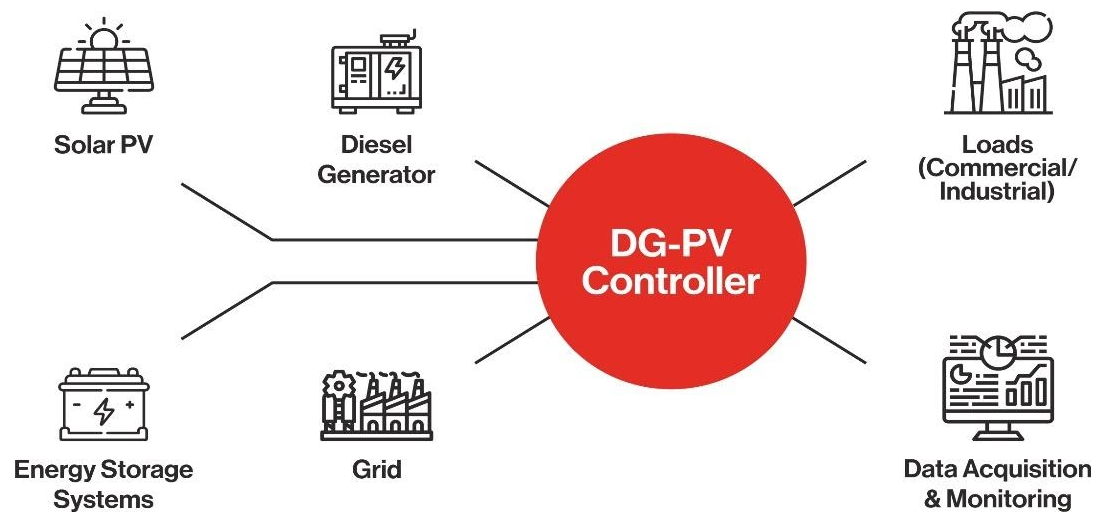

Battery Energy Storage System

Thermax provides specially designed battery energy storage systems with Li-ion technology to provide reliable and long backup. It also forms a hybrid system with solar PVs and solar power grid.

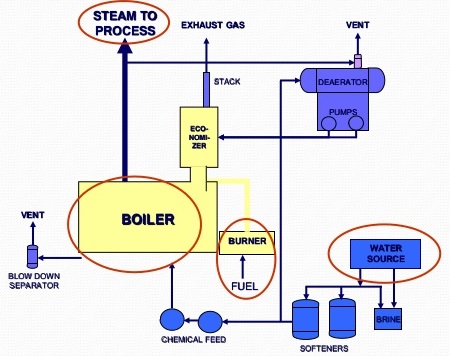

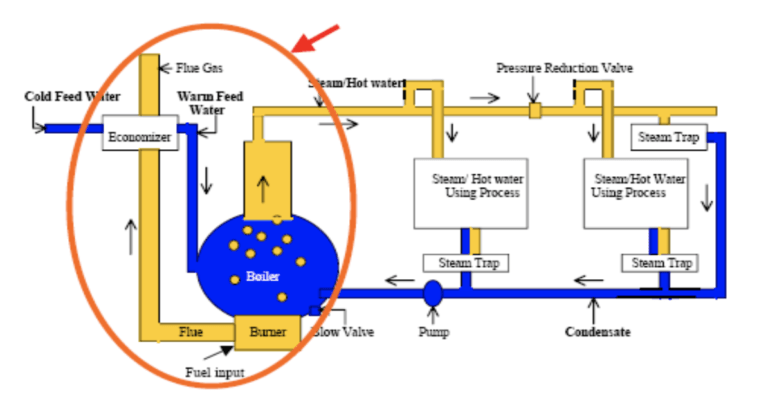

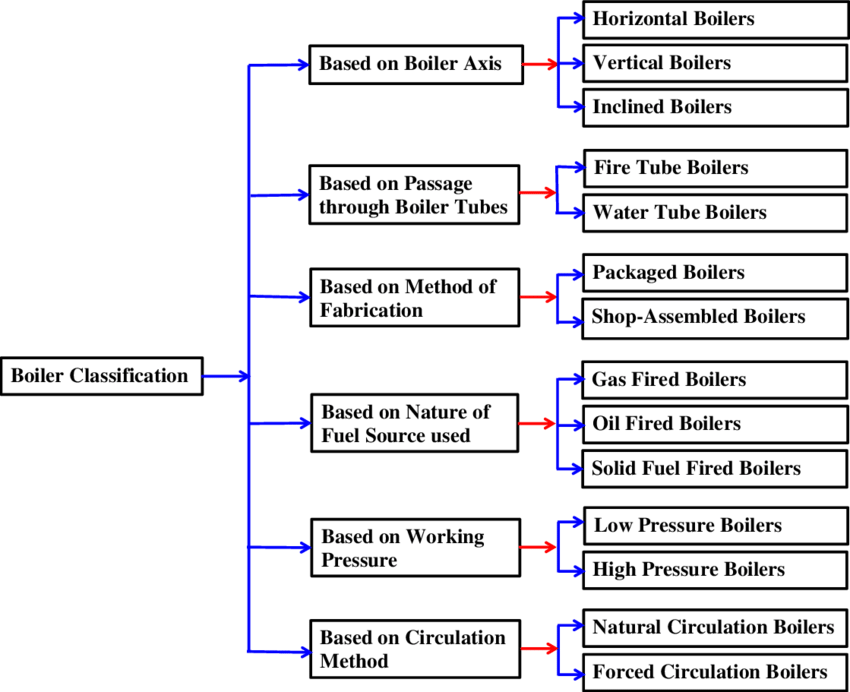

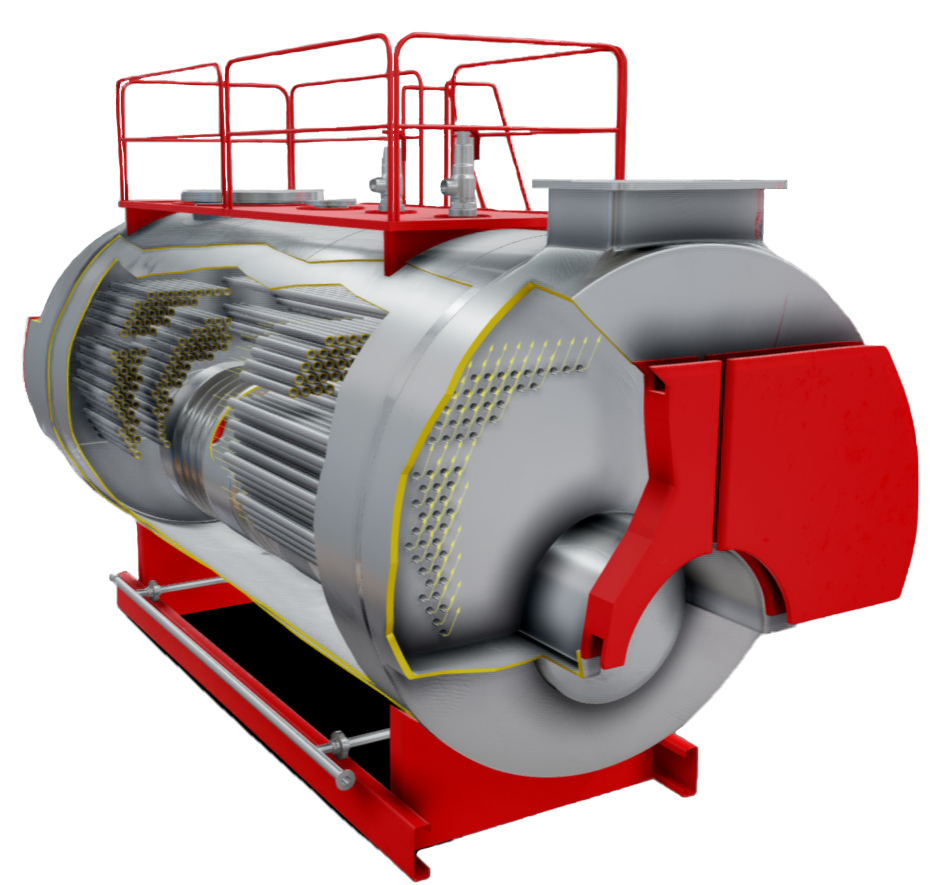

Biomass-Powered Boilers

Thermax offers various boilers with the capability of using biomass as the source of fuel instead of fossil fuels like coal/oil & gas without compromising on the quality of the output. These boilers have various benefits, including fuel flexibility, low maintenance, high efficiency, high availability, and reliability.

Travelling Grate Boilers

These are a highly efficient and reliable range of boilers that can run by combustion of a wide variety of biomass. They also allow precise control of grate speed and an over-fire air system. This system provides turbulence and thorough mixing of volatile gases, assuring complete combustion of biomass fuel.

Pinhole Grate Boilers

Pinhole Grate Boilers have a stationary inclined water-cooled grate design with no moving parts for avoiding any mechanical failures thus reducing maintenance costs for the furnace.

Pusher Grate Boilers

A unique boiler designed by Thermax for combustion of low calorific value in high moisture fuels with low maintenance requirements and high operational reliability.

Waste to Energy Boilers

Thermax has rich experience in providing clean and green solutions for converting waste products to generate clean energy.

Thermax offers a wide range of solutions for combustion of various fuels like – agriculture waste, spent wash, paper sludge, non-recyclable solid waste, refuse derived fuel, segregated municipal solid waste and other industrial process wastes.

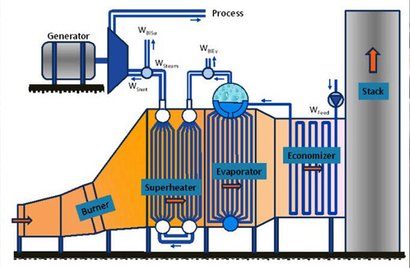

Waste Heat Recovery Boilers

Thermax provides energy solutions to utilise the excess heat from various processes and applications to improve overall energy balance in ferrous metals, non-ferrous metals, cement, refinery, chemical, oil & gas, glass, and other sectors. These offerings include a variety of customised, turnkey solutions to generate steam and power.

Spent Wash Fired Boilers

Thermax offers a unique solution for spent wash incineration to convert distillery waste to produce energy. This helps to adhere to the ‘Zero Liquid Discharge Regulatory Compliance’ and also helps in meeting the entire steam and power demand of the distillery industry.

Additionally, we provide outsourced utilities such as steam, heat, chilled water, treated water, power, and solar through the Build-Own-Operate (BOO/T) business model. We also undertake its comprehensive operation & maintenance along with supply chain management of all consumables, including biomass fuels.

As global emissions are reaching an alarming level, a shift to renewable sources of energy is inevitable. Thermax is also significantly investing in Research and Development (R&D) to tap new energy opportunities and devise unique applications focussed on creating a mark in the evolving sphere of energy transition, anchored towards a zero-carbon future.