Raw Mill – Kiln Application in Cement Industry

THE CUSTOMER PROFILE

M/s. Chettinad Cement Corporation Limited (CCCL), An Indian Rs 8.5 Billion business group is into Manufacturing (Cement, Silica, Quartz, Grits) & Services (Construction, Transports, Ship Management, Clearing & Forwarding), is one of the major cement manufacturers in Southern India with total cement production capacity of 3 MTPA having manufacturing units at Puliyur, Karur and Karikkali, Dindigul in Tamil Nadu.

APPLICATION CRITICALITY

The rotary kiln is the heart of a cement manufacturing plant. Cement kilns have all chemical ingredients. These

ingredients are at a broad range of gas temperatures from 100° to 1650°C.

The emissions contain:

- High concentrations of alkaline solids, including sodium and potassium oxides;

- High concentrations of freshly created Calcium Oxide

(CaO); - Volatiles; and

- Organic gases

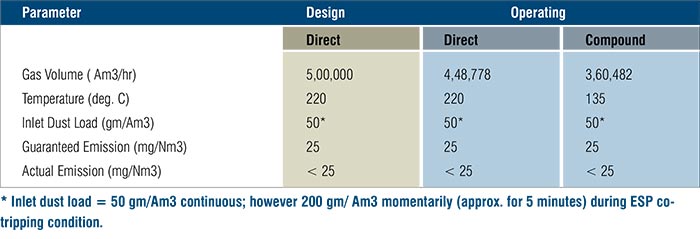

At CCCL, the kiln gases are at around 900 deg C. Pyroprocessing consists of five stages. Preheater exit gases are distributed based on requirement of Vertical Roller Mills for Raw Material Grinding and Vertical Roller Mill for Coal grinding. M/s CCCL has installed gas cooling system in the Preheater down-comer to bring the outlet gas temperature to about 310 deg C. In existing GCT, this temperature is further brought down to about 220 deg C and they are polished through the Air Pollution Control Equipment.

THE CHALLENGE

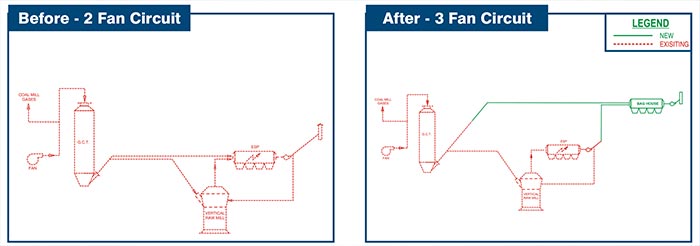

The Plant at Puliyur, Karur was operating at a capacity of 2,800 TPD clinker production. For the operation of the Raw Mill (Vertical Roller Mill), existing system was 2-fan circuit. The existing system consisted of Gas Conditioning Tower (GCT) followed by Electrostatic Precipitator (ESP) for the control of particulate emissions from the kiln and raw mill. Since the existing circuit was designed in early 90’s for lower capacity of Kiln, CCCL wanted to look at the various alternatives to reduce the emissions going out of the stack. CCCL decided after the initial scrutiny to award the work to m/s Thermax for suggesting various alternatives to meet the above objective. After much deliberation, Thermax and CCCL jointly decided that the best solution was to design a Bag House System in series with the existing ESP, (ESP – considered as a pre-collector). The system was guaranteed to give 25 mg/nm3 outlet emission with higher plant capacity.The system was converted from 2-fan circuit to 3- fan circuit. The major challenges handled by Thermax in designing the Bag House System in series with ESP were following:

- Handling very fine dust at the inlet for Bag House coming out after ESP

- Handling gases with higher moisture content coming out of the existing GCT.

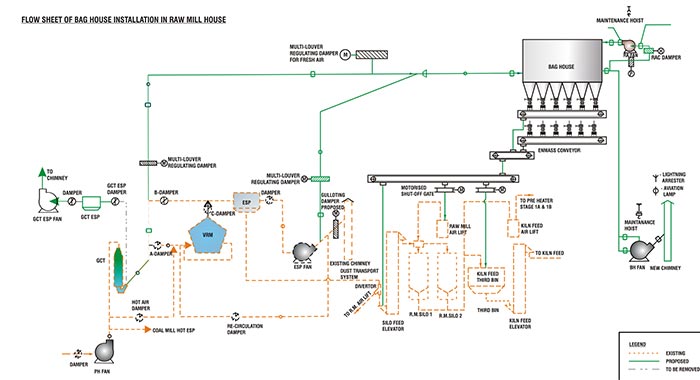

Like in any cement plant, the Bag House operates in two basic modes of operation:

- Direct Mode Of Operation – All the Preheater exit gases shall be routed directly to bag house since the raw mill is not operating

- Compound Mode Of Operation – Here the Raw Mill is in running condition, therefore major part of Preheater exit gases will be routed through the Raw Mill circuit( including Raw mill , ESP and ESP fan) before going through the baghouse.

THE THERMAX SOLUTION

The Reverse Air Bag House (RABH) was installed after ESP to handle the exit gases from Preheater / RawMill. After conducting thorough analysis on world wide similar reference installations for the suitability of filter media for achieving lower emissions, filter media / bags made up of Fibre Glass woven fabric along with Poly Tetra Fluro Ethylene (PTFE) laminate was selected for this installation. The chosen woven glass fabric posses the following characteristics:

- PTFE laminate is a micro porous membrane which collects even sub-micron sized particles

- It has excellent dust cake release property

- Due to its non-stick nature, it ensures low differential pressure across the fabric

- Also, PTFE laminate is moisture resistant and protects the woven glass fabric from effects of moisture.

- Mainly suitable for this application because of its inert nature, compatibility with the kiln gases and the

temperature resistance.

Bags of more than 10 meter length were used for optimum floor space usage. As an operating principle of RABH, periodically the bags are cleaned using the recirculation of the cleaned air from the outlet of the RABH. The dust collected from the bag house is transported to Silo / preheater feeding elevator.

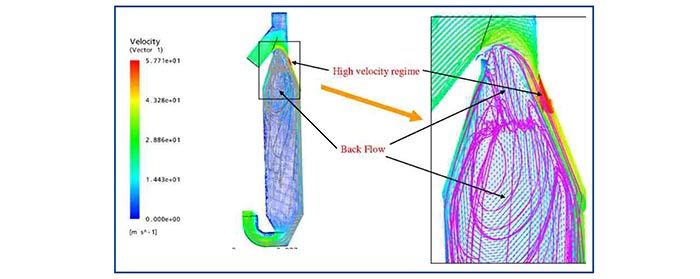

Having rich experience & expertise of more than 25 years in product line of ESP, Thermax recommended to charge only one out of three fields of this ESP which ensured the inlet dust load of bag house up to 50 mg/Am3 (from inlet dust load of 200 gm/Am3) and also maintained the outlet dust particle size from ESP in range of 10-15 microns which is good for the agglomeration. It was decided to conduct Computational Fluid Dynamics

(CFD) to analyze before hand, the fluid mechanics of gases with higher moisture content. Numerical methods and algorithms were extensively deployed to arrive at the proper and uniform distribution. CFD was used for the components at the development stage itself to optimize the effectiveness of the component before actual installation The outputs of the analysis were presented as color plots of velocities (arrow / contour) and pressure (contour) at

COMPLETE SCHEME

PROCESS PARAMETERS

COMPLETE SCHEME

Thermax was able to handle this complex issue of dust emission, through its extensive knowledge base of GCT, ESP and RABH technologies under one roof with requisite knowledge of the cement manufacturing process. As always, Thermax has once again delivered as per customer’s expectations in all respects and the emission levels are less than 25 mg/Nm3!!!!!