Gloves industry

Harness your industry's untapped heat with Thermax absorption cooling solutions and benefit from the electricity-free cooling

Gloves industry

Gloves serve as barriers of protection from infectious organisms and external agents, hence finding application across several fields – medical, manufacturing and packaging, etc. Natural rubber latex, due to its elasticity and tensile strength is the most preferred raw material for gloves manufacturing.

Latex collected from rubber trees is mixed with certain chemical compounds to stretch and stabilize the material. Liquid pigments are added to the latex to render the preferred colour to the gloves. The next step is vulcanizing the latex – which is crucial for offering resilience and elasticity to it. The latex is maintained hot so that it can be poured onto clean ceramic hand moulds, giving the gloves their shape. The latex-coated hand moulds are now dipped into a water bath. Chilled water in the bath rejects the heat from the gloves and cools them. Cooling the latex at the ideal temperature is of paramount importance to improve the gloves’ strength and elasticity. While preventing any rigidity, the chilled water also helps the gloves set in perfect shape avoiding the formation of air bubbles.

To cool the vulcanized latex for gloves, plant’s waste heat is used as the chiller’s heat source. By utilising on-site steam or hot water to drive the chillers, the cooling process has complete independence from the grid, which translates to negligible electricity usage and reduced emissions.

BENEFITS

- Electricity-free cooling

- Zero ozone depletion potential with water as refrigerant

- Grid-Independence

- Improved reliability

- Reduced operational costs

- Low maintenance costs

- Emission reduction

To know more about the application and benefits of our solutions, contact our experts now

OUR OFFERINGS

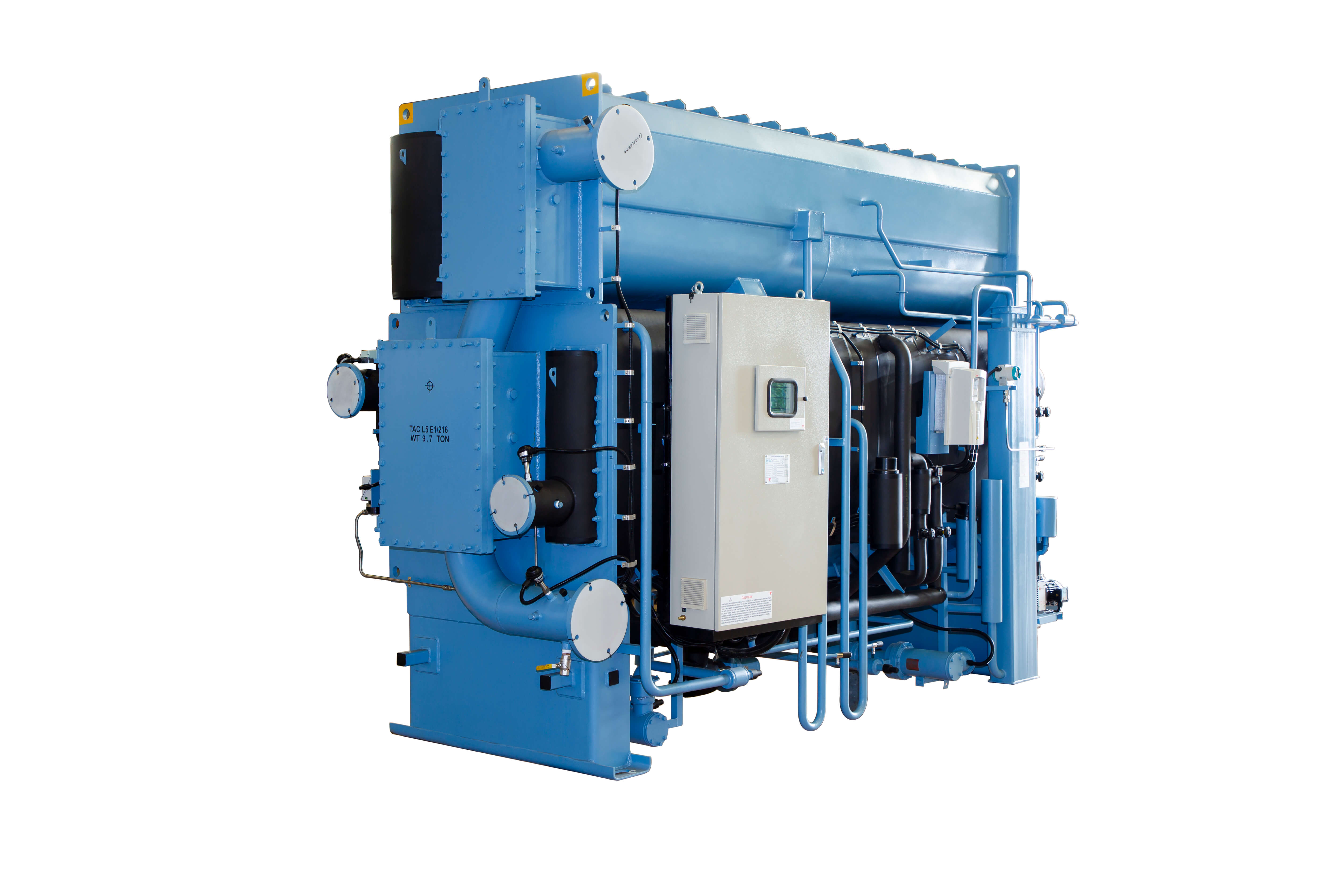

DOUBLE EFFECT STEAM FIRED VAPOUR ABSORPTION CHILLER

Heat Source: Steam

Pressure: 3 bar.g – 10.5 bar.g

COP: 1.5

Capacity: 50 – 3500 TR

Heat energy available in the form of

- Steam from boiler

- Steam from processes

- Steam from cogeneration plants

- Extraction from steam turbine

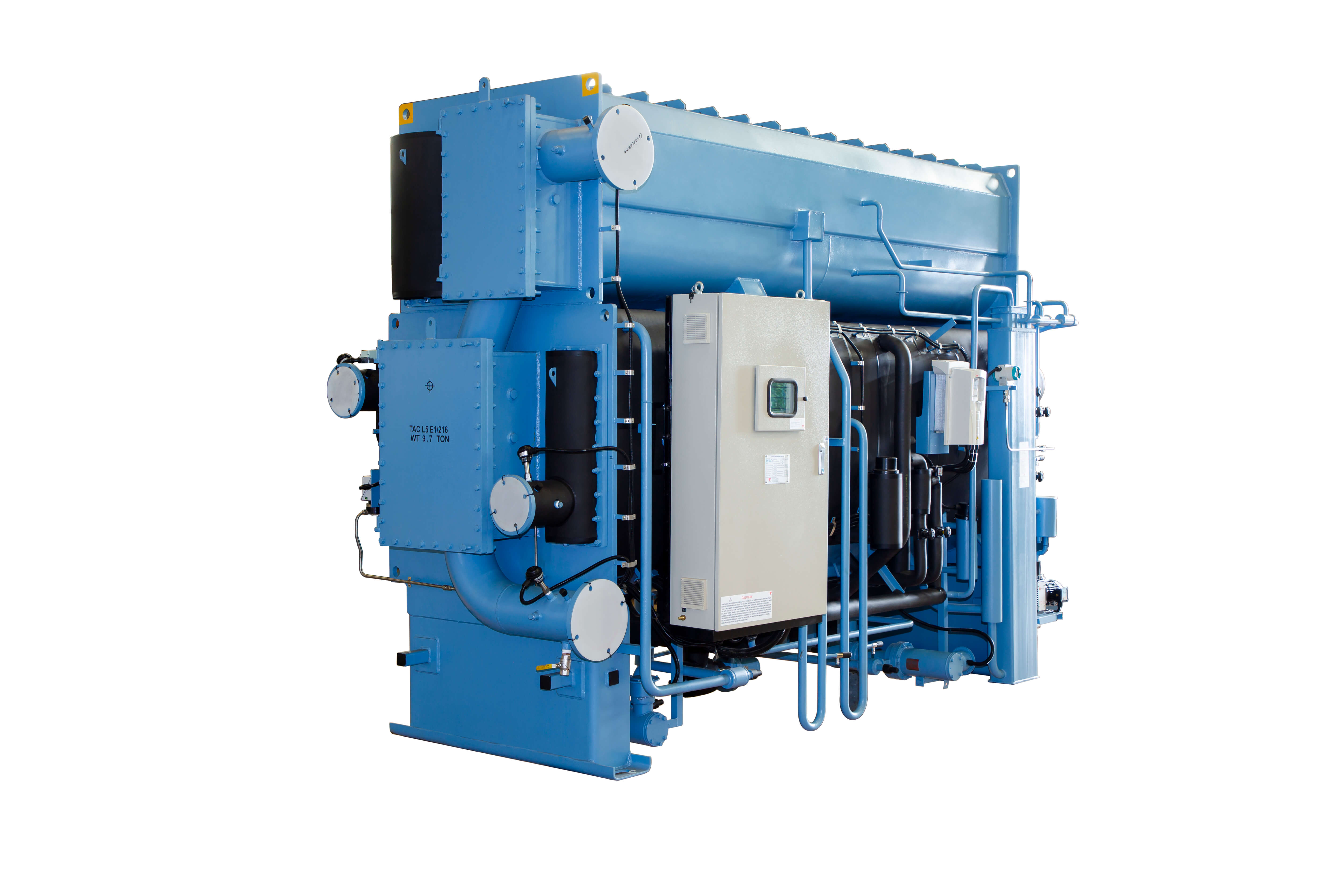

SINGLE EFFECT LOW TEMPERATURE HOT WATER DRIVEN VAPOUR ABSORPTION CHILLER

Heat Source: Hot Water

Inlet water temperature: 80OC – 120OC

COP: 0.8

Capacity: 180 – 1650 TR

Heat energy available in the form of

- Engine jacket water

- Hot water from solar collectors

- Process condensate

- Flue gas recovery from incinerators

- Process heat recovery

- Fuel cells

SINGLE EFFECT LOW TEMPERATURE HOT WATER DRIVEN VAPOUR ABSORPTION CHILLER

Heat Source: Hot Water

Inlet water temperature: 80OC – 120OC

COP: 0.8

Capacity: 180 – 1650 TR

Heat energy available in the form of

- Engine jacket water

- Hot water from solar collectors

- Process condensate

- Flue gas recovery from incinerators

- Process heat recovery

- Fuel cells

REFERENCES

WA Rubbermate

Location: Thailand

Machine type: Steam fired absorption chiller

Capacity: 150 TR

No. of machine: 1

Medisafe Technologies

Location: Indonesia

Machine type: Hot water driven absorption chiller

Capacity: 900 TR

No. of machine: 1