CONTROL ROOM COOLING

Realise the energy and economic benefits of absorption chillers in control room cooling. Heat mitigation has never been more energy-efficient and reliable

CONTROL ROOM COOLING

Control Room Cooling with Absorption Chillers

Absorption chillers are run by heat rather than electricity, potentially saving huge energy costs for the industry. Using heat sources like steam, hot water, thermic fluid, etc., to power the chillers offer significant energy gains while delivering chilled water at consistent temperature. Driven by recovered waste heat available in the plant, absorption chillers are the most reliable and sustainable solutions for control room cooling.

BENEFITS

- Reduced OPEX

- Optimised energy use

- Improvement in process reliability

- Better part load performance

- Reduced carbon emissions

- Waste heat recovery

To know more about the application and benefits of our solutions, contact our experts now

OUR OFFERINGS

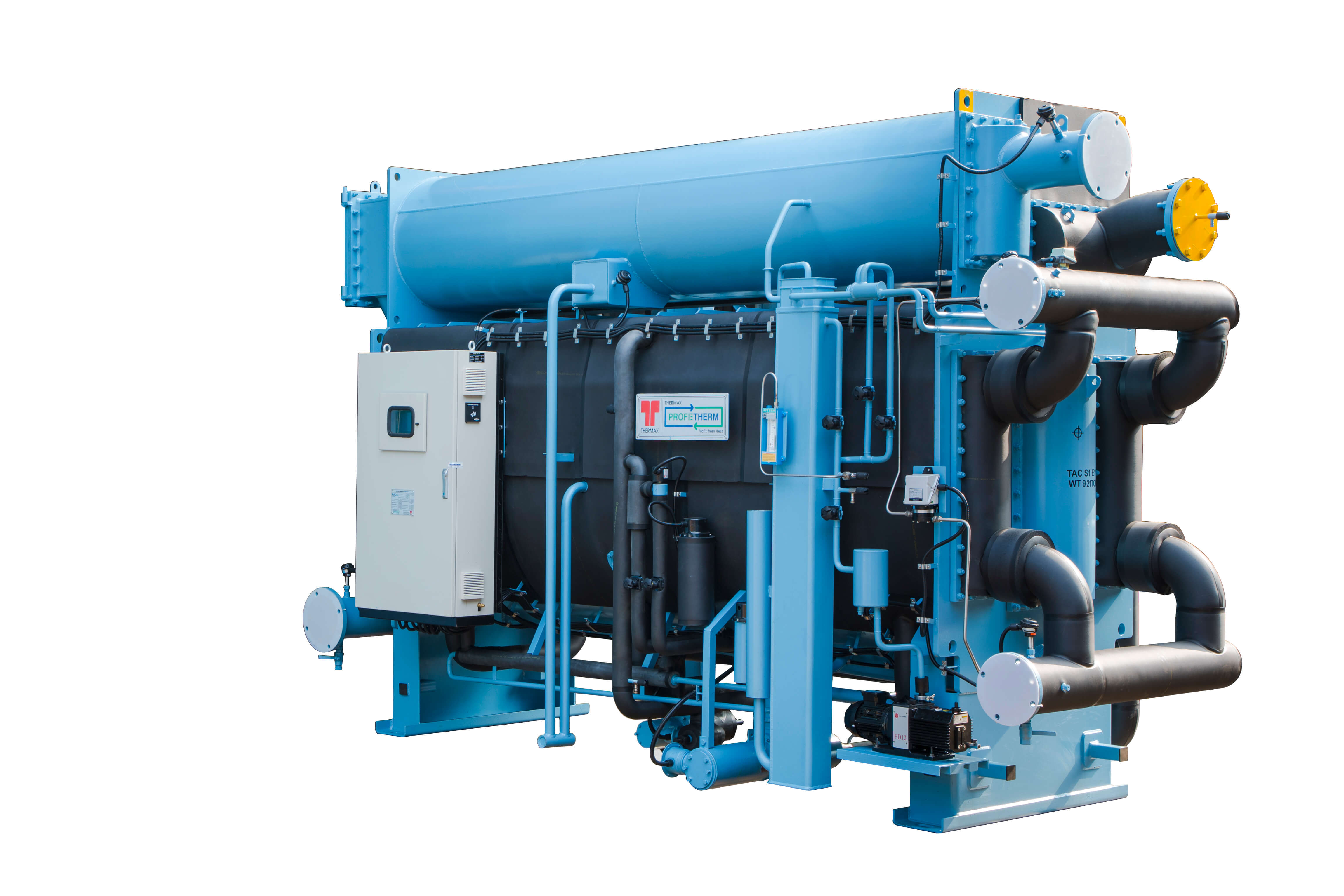

SINGLE EFFECT STEAM DRIVEN VAPOUR ABSORPTION CHILLER

Heat Source: Steam

Pressure: 0 bar.g – 3.5 bar.g

COP: 0.8

Capacity: 100 – 3500 TR

Heat energy available in the form of (LP- low pressure)

- LP vapour (0.1 bar.g, 103OC) coming from continuous polymerisation process in textile industry

- LP steam generated from potato fryer, instant noodle plant etc.

- LP Steam extraction from steam turbine in power plants

- Flash steam recovery

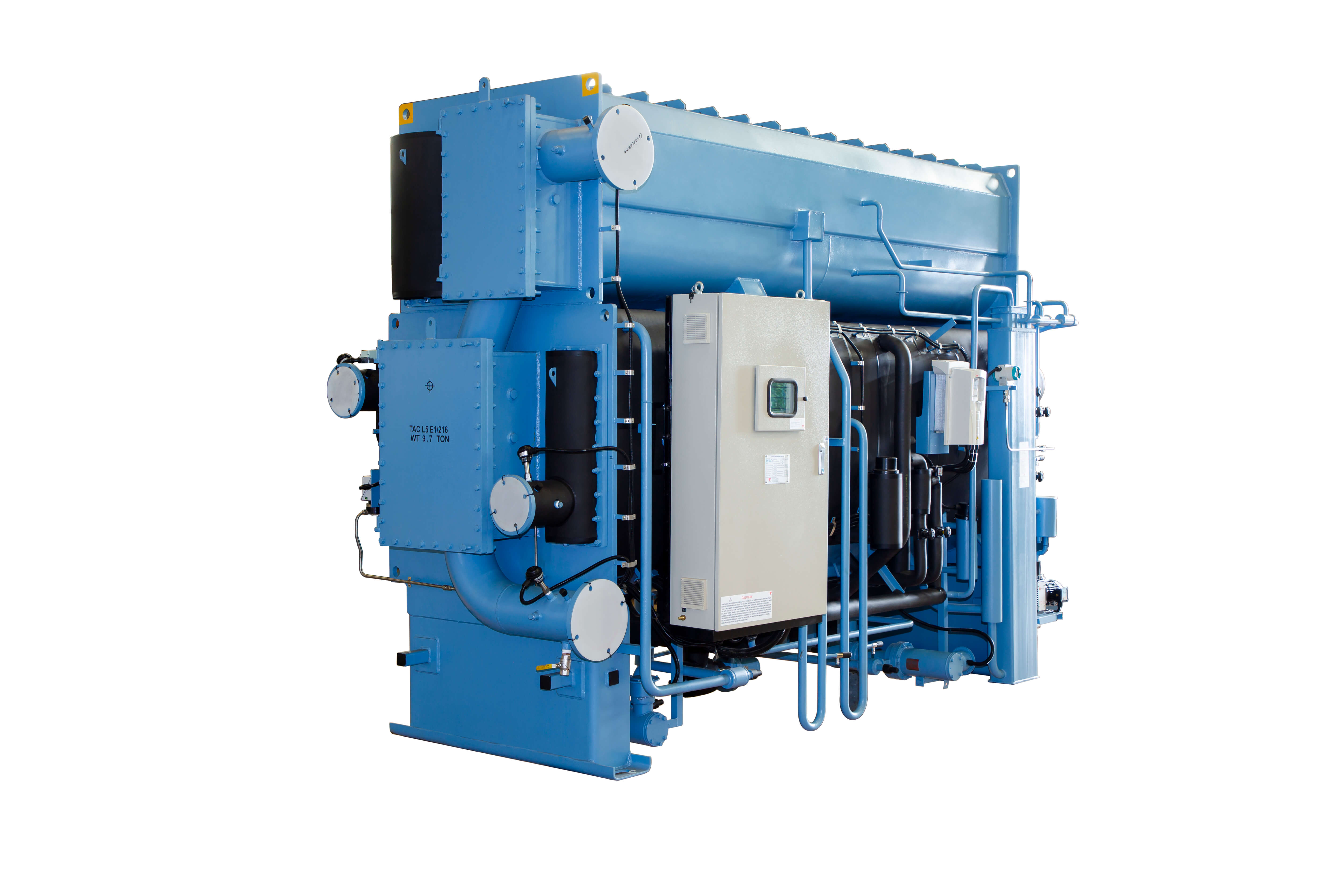

DOUBLE EFFECT STEAM FIRED VAPOUR ABSORPTION CHILLER

Heat Source: Steam

Pressure: 3 bar.g – 10.5 bar.g

COP: 1.5

Capacity: 50 – 3500 TR

Heat energy available in the form of

- Steam from boiler

- Steam from processes

- Steam from cogeneration plants

- Extraction from steam turbine

DOUBLE EFFECT STEAM FIRED VAPOUR ABSORPTION CHILLER

Heat Source: Steam

Pressure: 3 bar.g – 10.5 bar.g

COP: 1.5

Capacity: 50 – 3500 TR

Heat energy available in the form of

- Steam from boiler

- Steam from processes

- Steam from cogeneration plants

- Extraction from steam turbine

SINGLE EFFECT LOW TEMPERATURE HOT WATER DRIVEN VAPOUR ABSORPTION CHILLER

Heat Source: Hot Water

Inlet water temperature: 80OC – 120OC

COP: 0.8

Capacity: 180 – 1650 TR

Heat energy available in the form of

- Engine jacket water

- Hot water from solar collectors

- Process condensate

- Flue gas recovery from incinerators

- Process heat recovery

- Fuel cells

REFERENCES

Bansal Infratech

Chiller Type: Single effect steam fired vapour absorption chiller

Capacity: 1250 TR

No. of machine: 8

BMC Construction

Chiller Type: Double effect steam fired vapour absorption chiller

Capacity: 150 TR

No. of machine: 1

L&T

Chiller Type: Single effect steam fired vapour absorption chiller

Capacity: 460 TR

No. of machine: 2

Kapoor Industries Ltd

Chiller Type: Single effect steam fired vapour absorption chiller

Capacity: 150 TR

No. of machine: 1

Mythri Infra

Chiller Type: Single effect steam fired vapour absorption chiller

Capacity: 166 TR

No. of machine: 1